Control Cables – NBR 7289 / 7290 / 16442

Control cables – NBR 7290

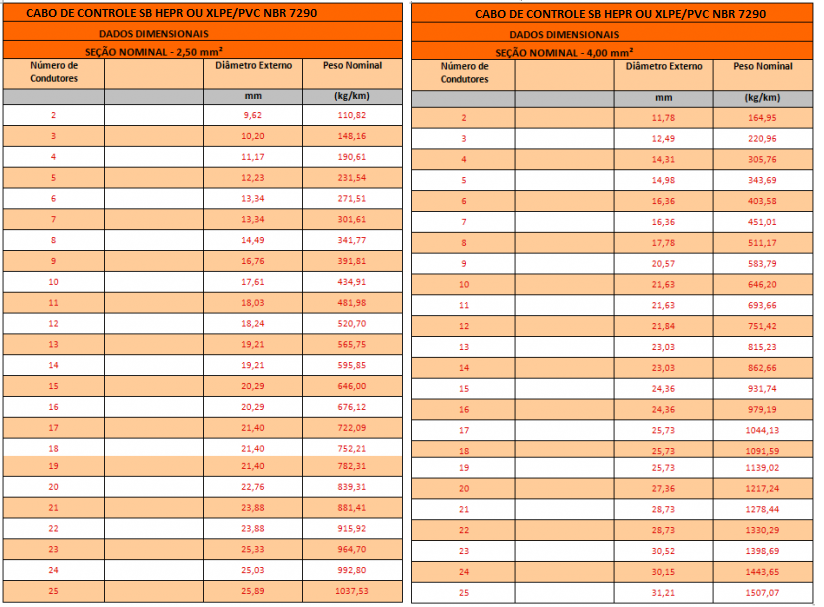

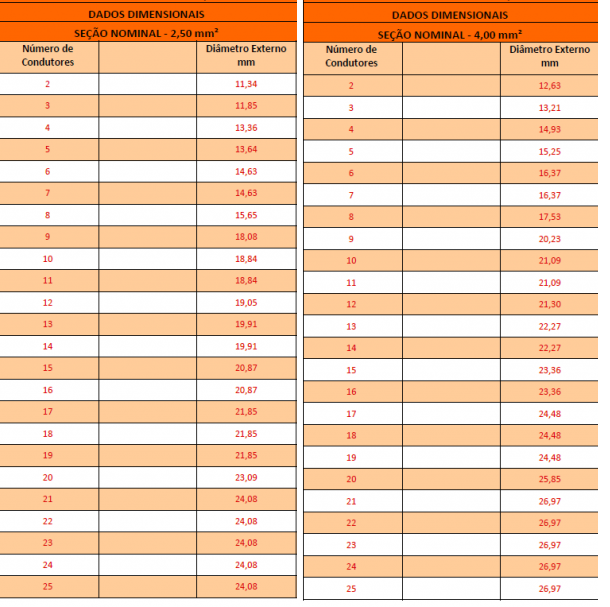

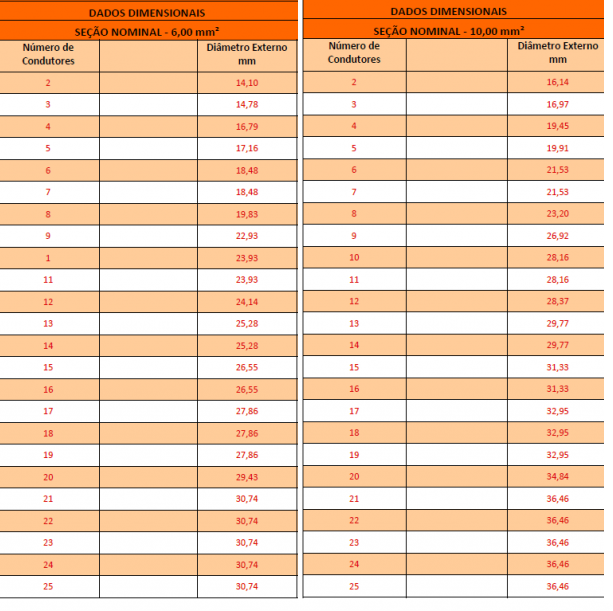

INNOVCABLE CONTROL CABLE SB XLPE-HEPR/PVC – NBR 7290

1) Stranded conductor formed by bare electrolytic copper wires, soft temper, class 5 NBR NM 280 stranding.

2) Composite insulation (HEPR – ethylene propylene rubber) or XLPE 90ºC.

3) Polyester tape separator.

4) Cover in thermoplastic compound based on polyvinyl chloride (PVC/ST1).

• Insulation voltage:

Up to 1.0mm² – 500V

From 1.50mm² to 10.00mm² – 1000V

• Routine tests:

Electrical resistance of the conductor at 20ºC

Electrical voltage in Alternating Current

Insulation resistance.

Identification

Black or white veins numbered sequentially, can be manufactured at the customer's request with a green vein (protective conductor). It can also be constructed with colored veins.

Applicable Specifications

Applications

They are used in fixed installations in control, command and signaling circuits of electrical equipment, structured cabling, machine connections, button panels, power supply, microprocessed systems, in automation of substations, generating plants, industrial and chemical areas, among others.

They are applied in fixed conduit systems (embedded or exposed), channels, duct banks, cable trays, beds, electrical panels, among other applications. This cable has good flexibility, resistance to UV, weather and humidity and certain chemicals.

Maximum Conductor Temperature

In steady state: +90°C

Maximum short circuit temperature: +250°C (5s)

Notes

The INNOVCABLE CONTROL CABLE SB XLPE-HEPR/PVC – NBR 7290 can be manufactured in another section, dimension or material at the customer's request. Innovcable reserves the right to change this catalog without prior notice.

OTHER CONSTRUCTION OPTIONS:

We can manufacture upon request in other configurations.

1- Tinned copper conductor.

Class 2 stringing.

2- Different sections and number of veins, maximum up to:

• 71 x 0.50mm² / 71 x 2.50mm²

• 52 x 4.00mm²

• 42 x 6.00mm²

• 20 x 10.0mm²

3- Vein insulation material / other temperatures:

PVC/E -105ºC

PVC/A – 70 ºC

PE – 80 ºC

4- Material of the intermediate layer and cover:

PE

PVC/E

PVC/ST2

Special PVC resistant to oils, greases and other chemical products.

LSZH (non-halogenated polyolefin compound).

5- Perfectly cylindrical cover for cable gland applications in hazardous areas (Ex)

INNOVCABLE CONTROL CABLE BF XLPE-HEPR/PVC – NBR 7290

1) Stranded conductor formed by bare electrolytic copper wires, soft temper, class 5 NBR NM 280 stranding.

2) Composite insulation (HEPR – ethylene propylene rubber) or XLPE 90ºC.

3) Separator in polyester tape and collective shielding in aluminized polyester tape with tinned copper drain wire.

4) Cover in thermoplastic compound based on polyvinyl chloride (PVC/ST1).

• Insulation voltage:

Up to 1.0mm² – 500V

From 1.50mm² to 10.00mm² – 1000V

• Routine tests:

Electrical resistance of the conductor at 20ºC

Electrical voltage in Alternating Current

Insulation resistance.

Identification

Black or white veins numbered sequentially, can be manufactured at the customer's request with a green vein (protective conductor). It can also be constructed with colored veins.

Applicable Specifications

Applications

They are used in fixed installations in control, command and signaling circuits of electrical equipment, structured cabling, machine connections, button panels, power supply, microprocessed systems, in automation of substations, generating plants, industrial and chemical areas, among others.

They are applied in fixed conduit systems (embedded or exposed), channels, duct banks, cable trays, beds, electrical panels, among other applications. It has collective protection in aluminized polyester tape against electromagnetic interference. This cable has good flexibility, resistance to UV, weather and humidity and certain chemicals.

Maximum Conductor Temperature

In steady state: +90°C

Maximum short circuit temperature: +250°C (5s)

Notes

The BF XLPE-HEPR/PVC CONTROL CABLE – NBR 7290 can be manufactured in another section, dimensional or material upon customer request. Innovcable reserves the right to change this catalog without prior notice.

CONSTRUCTION OPTIONS

We can manufacture upon request in other configurations.

1- Tinned copper conductor.

Class 2 stringing.

2- Different sections and number of veins, maximum up to:

• 71 x 0.50mm² / 71 x 2.50mm²

• 52 x 4.00mm²

• 42 x 6.00mm²

• 20 x 10.0mm²

3- Vein insulation material / other temperatures:

PVC/E -105ºC

PE – 80 ºC

4- Material Cover:

PE

PVC/E

PVC/ST2

Special PVC resistant to oils, greases and other chemicals.

5- Perfectly cylindrical cover for cable gland applications in hazardous areas (Ex).

INNOVCABLE BF FC XLPE-HEPR/PVC CONTROL CABLE – NBR 7290

1) Stranded conductor formed by bare electrolytic copper wires, soft temper, class 5 NBR NM 280 stranding.

2) Composite insulation (HEPR – ethylene propylene rubber) or XLPE 90ºC.

3) Separator in polyester tape and collective shielding in aluminized polyester tape with tinned copper drain wire.

4) Intermediate cover in thermoplastic compound based on polyvinyl chloride (PVC /ST1).

5) Copper tape shielding.

6) Non-hygroscopic tape.

7) Cover in thermoplastic compound based on polyvinyl chloride (PVC/ST1).

• Insulation voltage:

Up to 1.0mm² – 500V

From 1.50mm² to 10.00mm² – 1000V

• Routine tests:

Electrical resistance of the conductor at 20ºC

Electrical voltage in Alternating Current

Insulation resistance.

Identification

Black or white veins numbered sequentially, can be manufactured at the customer's request with a green vein (protective conductor). It can also be constructed with colored veins.

Applicable Specifications

Applications

They are used in fixed installations in control, command and signaling circuits of electrical equipment, structured cabling, machine connections, button panels, power supply, microprocessed systems, in automation of substations, generating plants, industrial and chemical areas, among others.

They are applied in fixed conduit systems (embedded or exposed), channels, duct banks, cable trays, beds, electrical panels, among other applications. It has collective protection in aluminized polyester tape and copper tape against electromagnetic interference. This cable has good flexibility, resistance to UV, weather and humidity and certain chemicals.

Maximum Conductor Temperature

In steady state: +90°C

Maximum short circuit temperature: +250°C (5s)

Notes

The BF FC XLPE-HEPR/PVC – NBR 7290 CONTROL CABLE can be manufactured in another section, dimensional or material upon customer request. Innovcable reserves the right to change this catalog without prior notice.

CONSTRUCTION OPTIONS

We can manufacture upon request in other configurations.

1- Tinned copper conductor.

Class 2 stringing.

2- Different sections and number of veins, maximum up to:

• 71 x 0.50mm² / 71 x 2.50mm²

• 52 x 4.00mm²

• 42 x 6.00mm²

• 20 x 10.0mm²

3- Vein insulation material / other temperatures:

PVC/E -105ºC

PVC/A – 70 ºC

PE – 80 ºC

4- Material of the intermediate layer and cover:

PE

PVC/E

PVC/ST2

Special PVC resistant to oils, greases and other chemical products.

LSZH (non-halogenated polyolefin compound).

5- Perfectly cylindrical cover for cable gland applications in hazardous areas (Ex)

INNOVCABLE BF FA XLPE-HEPR/PVC CONTROL CABLE – NBR 7290

1) Stranded conductor formed by bare electrolytic copper wires, soft temper, class 5 NBR NM 280 stranding.

2) Composite insulation (HEPR – ethylene propylene rubber) or XLPE 90ºC.

3) Separator in polyester tape and collective shielding in aluminized polyester tape with tinned copper drain wire.

4) Intermediate cover in thermoplastic compound based on polyvinyl chloride (PVC /ST1).

5) Galvanized steel strip shielding.

6) Non-hygroscopic tape.

7) Cover in thermoplastic compound based on polyvinyl chloride (PVC/ST1).

• Insulation voltage:

Up to 1.0mm² – 500V

From 1.50mm² to 10.00mm² – 1000V

• Routine tests:

Electrical resistance of the conductor at 20ºC

Electrical voltage in Alternating Current

Insulation resistance

Identification

Black or white veins numbered sequentially, can be manufactured at the customer's request with a green vein (protective conductor). It can also be constructed with colored veins.

Applicable Specifications

Applications

They are used in fixed installations in control, command and signaling circuits of electrical equipment, structured cabling, machine connections, button panels, power supply, microprocessed systems, in automation of substations, generating plants, industrial and chemical areas, among others.

They are applied in fixed conduit systems (embedded or exposed), channels, duct banks, cable trays, beds, electrical panels, among other applications. It has collective protection against electromagnetic interference and mechanical protection using galvanized steel tape. This cable has good flexibility, resistance to UV, weather and humidity and certain chemicals.

Maximum Conductor Temperature

In steady state: +90°C

Maximum short circuit temperature: +250°C (5s)

Notes

The BF FA XLPE-HEPR/PVC – NBR 7290 CONTROL CABLE can be manufactured in another section, dimensional or material upon customer request.

Innovcable reserves the right to change this catalog without prior notice.

CONSTRUCTION OPTIONS

We can manufacture upon request in other configurations.

1- Tinned copper conductor.

Class 2 stringing.

2- Different sections and number of veins, maximum up to:

• 71 x 0.50mm² / 71 x 2.50mm²

• 52 x 4.00mm²

• 42 x 6.00mm²

• 20 x 10.0mm²

3- Vein insulation material / other temperatures:

PVC/E -105ºC

PVC/A – 70 ºC

PE – 80 ºC

4- Material of the intermediate layer and cover:

PE

PVC/E

PVC/ST2

Special PVC resistant to oils, greases and other chemical products.

LSZH (non-halogenated polyolefin compound).

5- Perfectly cylindrical cover for cable gland applications in hazardous areas (Ex)

INNOVCABLE CONTROL CABLE BF BTC XLPE-HEPR/PVC – NBR 7290

1) Stranded conductor formed by bare electrolytic copper wires, soft temper, class 5 NBR NM 280 stranding.

2) Composite insulation (HEPR – ethylene propylene rubber) or XLPE 90ºC.

3) Separator in polyester tape and collective shielding in aluminized polyester tape with tinned copper drain wire.

4) Intermediate cover in thermoplastic compound based on polyvinyl chloride (PVC /ST1).

5) Copper braid shielding.

6) Non-hygroscopic tape.

7) Cover in thermoplastic compound based on polyvinyl chloride (PVC/ST1).

• Insulation voltage:

Up to 1.0mm² – 500V

From 1.50mm² to 10.00mm² – 1000V

• Routine tests:

Electrical resistance of the conductor at 20ºC

Electrical voltage in Alternating Current

Insulation resistance.

Identification

Black or white veins numbered sequentially, can be manufactured at the customer's request with a green vein (protective conductor). It can also be constructed with colored veins.

Applicable Specifications

Applications

They are used in fixed installations in control, command and signaling circuits of electrical equipment, structured cabling, machine connections, button panels, power supply, microprocessed systems, in automation of substations, generating plants, industrial and chemical areas, among others.

They are applied in fixed conduit systems (embedded or exposed), channels, duct banks, cable trays, beds, electrical panels, among other applications. It has collective protection in aluminized polyester tape and copper braid against electromagnetic interference. This cable has good flexibility, resistance to UV, weather and humidity and certain chemicals.

Maximum Conductor Temperature

In steady state: +90°C

Maximum short circuit temperature: +250°C (5s)

Notes

The BF BTC XLPE-HEPR/PVC – NBR 7290 CONTROL CABLE can be manufactured in another section, dimensional or material upon customer request.

Innovcable reserves the right to change this catalog without prior notice.

CONSTRUCTION OPTIONS

We can manufacture upon request in other configurations.

1- Tinned copper conductor.

Class 2 stringing.

2- Different sections and number of veins, maximum up to:

• 71 x 0.50mm² / 71 x 2.50mm²

• 52 x 4.00mm²

• 42 x 6.00mm²

• 20 x 10.0mm²

3- Vein insulation material / other temperatures:

PVC/E -105ºC

PVC/A – 70 ºC

PE – 80 ºC

4- Material of the intermediate layer and cover:

PE

PVC/E

PVC/ST2

Special PVC resistant to oils, greases and other chemical products.

LSZH (non-halogenated polyolefin compound).

5- Perfectly cylindrical cover for cable gland applications in hazardous areas (Ex)

INNOVCABLE CONTROL CABLE BF BTA XLPE-HEPR/PVC – NBR 7290

1) Stranded conductor formed by bare electrolytic copper wires, soft temper, class 5 NBR NM 280 stranding.

2) Composite insulation (HEPR – ethylene propylene rubber) or XLPE 90ºC.

3) Separator in polyester tape and collective shielding in aluminized polyester tape with tinned copper drain wire.

4) Intermediate cover in thermoplastic compound based on polyvinyl chloride (PVC /ST1).

5) Galvanized steel braid shielding.

6) Non-hygroscopic tape.

7) Cover in thermoplastic compound based on polyvinyl chloride (PVC/ST1).

• Insulation voltage:

Up to 1.0mm² – 500V

From 1.50mm² to 10.00mm² – 1000V

• Routine tests:

Electrical resistance of the conductor at 20ºC

Electrical voltage in Alternating Current

Insulation resistance.

Identification

Black or white veins numbered sequentially, can be manufactured at the customer's request with a green vein (protective conductor). It can also be constructed with colored veins.

Applicable Specifications

Applications

They are used in fixed installations in control, command and signaling circuits of electrical equipment, structured cabling, machine connections, button panels, power supply, microprocessed systems, in automation of substations, generating plants, industrial and chemical areas, among others.

They are applied in fixed conduit systems (embedded or exposed), channels, duct banks, cable trays, beds, electrical panels, among other applications. It has collective protection against electromagnetic interference and mechanical protection of galvanized steel braid. This cable has good flexibility, resistance to UV, weather and humidity and certain chemicals.

Maximum Conductor Temperature

In steady state: +90°C

Maximum short circuit temperature: +250°C (5s)

Notes

The BF BTA XLPE-HEPR/PVC – NBR 7290 CONTROL CABLE can be manufactured in another section, dimensional or material upon customer request.

Innovcable reserves the right to change this catalog without prior notice.

CONSTRUCTION OPTIONS

We can manufacture upon request in other configurations.

1- Tinned copper conductor.

Class 2 stringing.

2- Different sections and number of veins, maximum up to:

• 71 x 0.50mm² / 71 x 2.50mm²

• 52 x 4.00mm²

• 42 x 6.00mm²

• 20 x 10.0mm²

3- Vein insulation material / other temperatures:

PVC/E -105ºC

PVC/A – 70 ºC

PE – 80 ºC

4- Material of the intermediate layer and cover:

PE

PVC/E

PVC/ST2

Special PVC resistant to oils, greases and other chemical products.

LSZH (non-halogenated polyolefin compound).

5- Perfectly cylindrical cover for cable gland applications in hazardous areas (Ex)

INNOVCABLE BTC XLPE-HEPR/PVC CONTROL CABLE – NBR 7290

1) Stranded conductor formed by bare electrolytic copper wires, soft temper, class 5 NBR NM 280 stranding.

2) Composite insulation (HEPR – ethylene propylene rubber) or XLPE 90ºC.

3) Polyester tape separator.

4) Intermediate cover in thermoplastic compound based on polyvinyl chloride (PVC /ST1).

5) Bare copper braid shielding.

6) Non-hygroscopic tape.

7) Cover in thermoplastic compound based on polyvinyl chloride (PVC/ST1).

•Insulation voltage:

Up to 1.0mm² – 500V

From 1.50mm² to 10.00mm² – 1000V

•Routine tests:

Electrical resistance of the conductor at 20ºC

Electrical voltage in Alternating Current

Insulation resistance.

Identification

Black or white veins numbered sequentially, can be manufactured at the customer's request with a green vein (protective conductor). It can also be constructed with colored veins.

Applicable Specifications

Applications

They are used in fixed installations in control, command and signaling circuits of electrical equipment, structured cabling, machine connections, button panels, power supply, microprocessed systems, in automation of substations, generating plants, industrial and chemical areas, among others.

They are applied in fixed conduit systems (embedded or exposed), channels, duct banks, cable trays, beds, electrical panels, among other applications. It has protection against EMV electromagnetic interference. This cable has good flexibility, resistance to UV, weather and humidity and certain chemicals.

Maximum Conductor Temperature

In steady state: +90°C

Maximum short circuit temperature: +250°C (5s)

Notes

The BTC XLPE-HEPR/PVC – NBR 7290 CONTROL CABLE can be manufactured in another section, dimensional or material upon customer request.

Innovcable reserves the right to change this catalog without prior notice.

CONSTRUCTION OPTIONS

We can manufacture upon request in other configurations.

1- Tinned copper conductor.

Class 2 stringing.

2- Different sections and number of veins, maximum up to:

• 71 x 0.50mm² / 71 x 2.50mm²

• 52 x 4.00mm²

• 42 x 6.00mm²

• 20 x 10.0mm²

3- Vein insulation material / other temperatures:

PVC/E -105ºC

PVC/A – 70 ºC

PE – 80 ºC

4- Material of the intermediate layer and cover:

PE

PVC/E

PVC/ST2

Special PVC resistant to oils, greases and other chemical products.

LSZH (non-halogenated polyolefin compound).

5- Perfectly cylindrical cover for cable gland applications in hazardous areas (Ex)

INNOVCABLE BTA XLPE-HEPR/PVC CONTROL CABLE – NBR 7290

1) Stranded conductor formed by bare electrolytic copper wires, soft temper, class 5 NBR NM 280 stranding.

2) Composite insulation (HEPR – ethylene propylene rubber) or XLPE 90ºC.

3) Polyester tape separator.

4) Intermediate cover in thermoplastic compound based on polyvinyl chloride (PVC /ST1).

5) Galvanized steel braid shielding.

6) Non-hygroscopic tape.

7) Cover in thermoplastic compound based on polyvinyl chloride (PVC/ST1).

• Insulation voltage:

Up to 1.0mm² – 500V

From 1.50mm² to 10.00mm² – 1000V

• Routine tests:

Electrical resistance of the conductor at 20ºC

Electrical voltage in Alternating Current

Insulation resistance.

Identification

Black or white veins numbered sequentially, can be manufactured at the customer's request with a green vein (protective conductor). It can also be constructed with colored veins.

Applicable Specifications

Applications

They are used in fixed installations in control, command and signaling circuits of electrical equipment, structured cabling, machine connections, button panels, power supply, microprocessed systems, in automation of substations, generating plants, industrial and chemical areas, among others.

They are applied in fixed conduit systems (embedded or exposed), channels, duct banks, cable trays, beds, electrical panels, among other applications. It has mechanical protection made of galvanized steel braid. This cable has good flexibility, resistance to UV, weather and humidity and certain chemicals.

Maximum Conductor Temperature

In steady state: +90°C

Maximum short circuit temperature: +250°C (5s)

Notes

The BTA XLPE-HEPR/PVC – NBR 7290 CONTROL CABLE can be manufactured in another section, dimensional or material upon customer request.

Innovcable reserves the right to change this catalog without prior notice.

CONSTRUCTION OPTIONS

We can manufacture upon request in other configurations.

1- Tinned copper conductor.

Class 2 stringing.

2- Different sections and number of veins, maximum up to:

• 71 x 0.50mm² / 71 x 2.50mm²

• 52 x 4.00mm²

• 42 x 6.00mm²

• 20 x 10.0mm²

3- Vein insulation material / other temperatures:

PVC/E -105ºC

PVC/A – 70 ºC

PE – 80 ºC

4- Material of the intermediate layer and cover:

PE

PVC/E

PVC/ST2

Special PVC resistant to oils, greases and other chemical products.

LSZH (non-halogenated polyolefin compound).

5- Perfectly cylindrical cover for cable gland applications in hazardous areas (Ex)

INNOVCABLE BFA XLPE-HEPR/PVC CONTROL CABLE – NBR 7290

1) Stranded conductor formed by bare electrolytic copper wires, soft temper, class 5 NBR NM 280 stranding.

2) Composite insulation (HEPR – ethylene propylene rubber) or XLPE 90ºC.

3) Polyester tape separator.

4) Intermediate cover in thermoplastic compound based on polyvinyl chloride (PVC /ST1).

5) Galvanized steel strip shielding.

6) Non-hygroscopic tape, if applicable.

7) Cover in thermoplastic compound based on polyvinyl chloride (PVC/ST1).

• Insulation voltage:

Up to 1.0mm² – 500V

From 1.50mm² to 10.00mm² – 1000V

• Routine tests:

Electrical resistance of the conductor at 20ºC

Electrical voltage in Alternating Current

Insulation resistance.

Identification

Black or white veins numbered sequentially, can be manufactured at the customer's request with a green vein (protective conductor). It can also be constructed with colored veins.

Applicable Specifications

Applications

They are used in fixed installations in control, command and signaling circuits of electrical equipment, structured cabling, machine connections, button panels, power supply, microprocessed systems, in automation of substations, generating plants, industrial and chemical areas, among others.

They are applied in fixed conduit systems (embedded or exposed), channels, duct banks, cable trays, beds, electrical panels, among other applications. It has mechanical protection made of galvanized steel tape. This cable has good flexibility, resistance to UV, weather and humidity and certain chemicals.

Maximum Conductor Temperature

EIn steady state: +90°C

Maximum short circuit temperature: +250°C (5s)

Notes

The BFA XLPE-HEPR/PVC – NBR 7290 CONTROL CABLE can be manufactured in another section, dimensional or material upon customer request.

Innovcable reserves the right to change this catalog without prior notice.

CONSTRUCTION OPTIONS

We can manufacture upon request in other configurations.

1- Tinned copper conductor.

Class 2 stringing.

2- Different sections and number of veins, maximum up to:

• 71 x 0.50mm² / 71 x 2.50mm²

• 52 x 4.00mm²

• 42 x 6.00mm²

• 20 x 10.0mm²

3- Vein insulation material / other temperatures:

PVC/E -105ºC

PVC/A – 70 ºC

PE – 80 ºC

4- Material of the intermediate layer and cover:

PE

PVC/E

PVC/ST2

Special PVC resistant to oils, greases and other chemical products.

LSZH (non-halogenated polyolefin compound).

5- Perfectly cylindrical cover for cable gland applications in hazardous areas (Ex)

INNOVCABLE BFC XLPE-HEPR/PVC CONTROL CABLE – NBR 7290

1) Stranded conductor formed by bare electrolytic copper wires, soft temper, class 5 NBR NM 280 stranding.

2) Composite insulation (HEPR – ethylene propylene rubber) or XLPE 90ºC.

3) Polyester tape separator.

4) Intermediate cover in thermoplastic compound based on polyvinyl chloride (PVC /ST1).

5) Copper tape shielding.

6) Non-hygroscopic tape, if applicable.

7) Cover in thermoplastic compound based on polyvinyl chloride (PVC/ST1).

• Insulation voltage:

Up to 1.0mm² – 500V

From 1.50mm² to 10.00mm² – 1000V

• Routine tests:

Electrical resistance of the conductor at 20ºC

Electrical voltage in Alternating Current

Insulation resistance.

Identification

Black or white veins numbered sequentially, can be manufactured at the customer's request with a green vein (protective conductor). It can also be constructed with colored veins.

Applicable Specifications

Applications

They are used in fixed installations in control, command and signaling circuits of electrical equipment, structured cabling, machine connections, button panels, power supply, microprocessed systems, in automation of substations, generating plants, industrial and chemical areas, among others.

They are applied in fixed conduit systems (embedded or exposed), channels, duct banks, cable trays, beds, electrical panels, among other applications. It has copper tape protection against electromagnetic interference. This cable has good flexibility, resistance to UV, weather and humidity and certain chemicals.

Maximum Conductor Temperature

In steady state: +90°C

Maximum short circuit temperature: +250°C (5s)

Notes

The BFC XLPE-HEPR/PVC – NBR 7290 CONTROL CABLE can be manufactured in another section, dimensional or material upon customer request.

Innovcable reserves the right to change this catalog without prior notice.

CONSTRUCTION OPTIONS

We can manufacture upon request in other configurations.

1- Tinned copper conductor.

Class 2 stringing.

2- Different sections and number of veins, maximum up to:

• 71 x 0.50mm² / 71 x 2.50mm²

• 52 x 4.00mm²

• 42 x 6.00mm²

• 20 x 10.0mm²

3- Vein insulation material / other temperatures:

PVC/E -105ºC

PVC/A – 70 ºC

PE – 80 ºC

4- Material of the intermediate layer and cover:

PE

PVC/E

PVC/ST2

Special PVC resistant to oils, greases and other chemical products.

LSZH (non-halogenated polyolefin compound).

5- Perfectly cylindrical cover for cable gland applications in hazardous areas (Ex)