Naval Cables – IEC Standard

Naval instrumentation cables 150/250V (300V)

INNOVCABLE INNOVSHORE CONTROL / INSTRUMENTATION 150/250V (300V)

- Conductor made up of bare or tinned electrolytic copper wires, soft temper, class 5 stranding, in accordance with IEC 60228.*1.7

- Insulation of conductors in special halogen-free compound LSOH (HF-90). *4

- Final cover in halogen-free polyolefin compound LSOH (SHF1), gray in color. *2.5

Identification

– External Recording:

INNOVCABLE INNOVSHORE CONTROL/INSTRUMENTATION __mm² 0.15/0.25KV 90°C OF: XXXX/YEAR

Of the conductors – white or black insulation numbered sequentially. *3

Applicable Specifications

Applications

Built and designed for the demanding offshore drilling environment and the naval industry.

Used on board ships in fixed facilities, trays, gutters, conduits, panels, among others. Naval cables Instrumentation are indicated for use in control, command and signaling circuits in accordance with IEC 60092-352. Innovshore control/instrumentation cables 0.15/0.25kV offers maximum resistance to chemicals, humidity and UV rays. Naval cables Instrumentation are non-halogen and improvement under fire, anti-flame, does not produce toxic and corrosive gases. Exceed the specifications of the indicated IEC's.

Maximum Conductor Temperature

CONTINUOUS SERVICE: 90°C – IEC 60092-360

SHORT CIRCUIT: 250°C

Notes

* We manufacture with other configurations:

1) The tinned copper conductor can be manufactured in class 2.

2) External cover colors: Nomenclature to be added to the end of the code: VM – Red // VD – Green // BR – White // PT – Black // AZ – Blue

We can manufacture other colors upon request.

3) Different sections and number of veins, maximum up to:

• 71 x 0.50mm² / 71 x 2.50mm²

• 52 x 4.00mm²

• 42 x 6.00mm²

• 20 x 10.0mm²

4) Vein insulation material:

EPR – 90 ºC

HEPR – 90 ºC

XLPE – 90 ºC

5) Material of the intermediate layer and cover:

ST2

SE

SHF2

6) At Innovcable's discretion, separators and/or fillings made of compatible material may be used.

7) Nomenclature to be added to the end of the code depending on the type of conductor:

Bare copper conductor – CN

Tinned copper conductor – SN

Naval cables instrumentation

**Innovcable reserves the right to change this catalog without prior notice.**

INNOVCABLE INNOVSHORE CONTROL / INSTRUMENTATION SHIELDED BTC/BTS 150/250V (300V)

1) Conductor formed by bare or tinned electrolytic copper wires, soft temper, class 5 stranding, in accordance with IEC 60228. *1.7

2) Insulation of conductors in special halogen-free compound LSOH (HF-90). *4

3) Banding or extruded filling.

4) Shielding: Braid of bare copper (BTC) or tinned copper (BTS) wires with >90% coverage. *8

5) Final cover in halogen-free polyolefin compound LSOH (SHF1), gray in color. *2.5

Identification

External Recording:

INNOVSHORE SHIELDED CONTROL/INSTRUMENTATION CABLE BTC/BTS __ x __mm² 0.15/0.25KV 90°C OF: XXXX/YEAR

Of the conductors – white or black insulation numbered sequentially. *3

Applicable Specifications

Applications

Built and designed for the demanding offshore drilling environment and the naval industry.

It has excellent protection against electromagnetic interference.

They are used in fixed facilities, trays, gutters, conduits, panels, among others. Naval cables Instrumentation are indicated for use in control, command and signaling circuits, feeding, machine connection, among other environments. Innovshore cable cables control/instrumentation BTC/BTS 0.15/0.25kV offers maximum resistance to chemicals, humidity and UV rays. No halogen and improvement under fire, anti-flame, does not produce toxic and corrosive gases. Exceed the specifications of the indicated IEC's.

Maximum Conductor Temperature

CONTINUOUS SERVICE: 90°C – IEC 60092-360

SHORT CIRCUIT: 250°C

Notes

* We manufacture with other configurations:

1) The tinned copper conductor can be manufactured in class 2.

2) External cover colors: Nomenclature to be added to the end of the code: VM – Red // VD – Green // BR – White // PT – Black // AZ – Blue

We can manufacture other colors upon request.

3) Different sections and number of veins.

)

Vein insulation material:

EPR

– 90

ºC

HEPR – 90

ºC compatible. 7) Nomenclature to be added to the end of the code depending on the type of conductor:

Bare copper conductor – CN

Tinned copper conductor – SN

8) Types of shielding:

BTS – Braided shielding of tinned copper wires

BTC – Braided shielding of bare copper wires

Naval cables instrumentation

**Innovcable reserves the right to change this catalog without prior notice.**

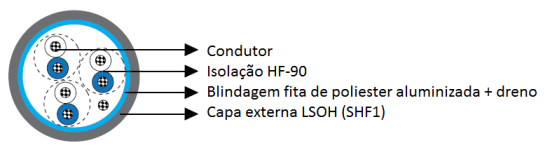

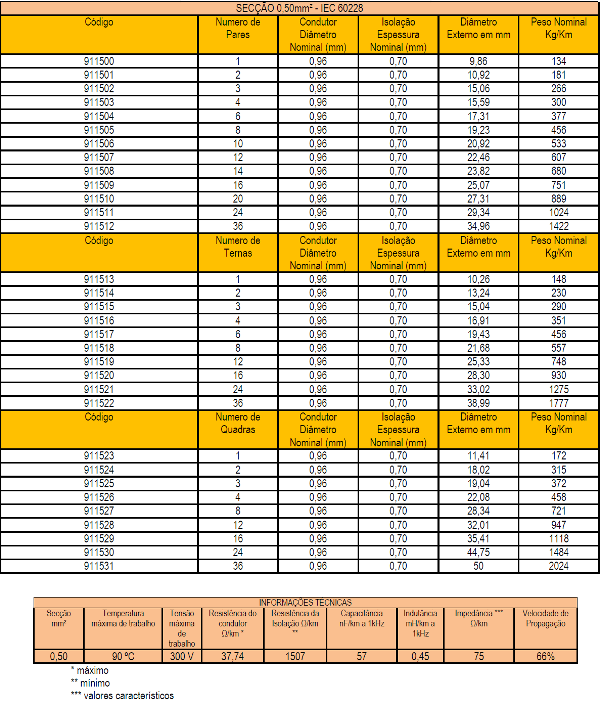

INNOVCABLE INNOVSHORE SHIELDED INSTRUMENTATION BF 0.15/0.25KV (300V)

1) Conductor formed by bare or tinned electrolytic copper wires, soft temper, class 5 stranding. IEC 60228. *1.7

2) Insulation in special halogen-free compound LSOH (HF-90). *4

3) Communication conductor with 0.5mm² section, in LSOH compound (HF-90), Identification through blue insulation (only for cables with 2 or more pairs, triples or quads) – (Optional). *4

4) Collective shielding in aluminum-polyester tape, with flexible drain conductor, formed by tinned electrolytic copper wires, soft temper.

5) Cover in halogen-free polyolefin compound LSOH (SHF1), gray in color. *2.5

Identification

– External Recording:

INNOVCABLE INNOVSHORE INSTRUMENTATION BF __mm² 0.15/0.25KV (300V) 90°C OF: XXXX/YEAR.

Of the conductors – through the colors of the insulation, being:

black and white (cables in pairs)

black, white and red (cables in bundles).

black, white, red and green (cables in blocks).*3

Identification through sequential numbering.

Applicable Specifications

Applications

Built and designed for the demanding offshore drilling environment and the naval industry.

Naval cables Instrumentation are used in fixed installations, conducting analog (4 - 20MA) and digital signals, point -to -point instrumentation, Hart ® protocol, various sensor connections and meters, conventional and electronic relay feed, in general industrial environments. Innovshore instrumentation cables BF armored instrumentation are recommended in cases where excellent levels of protection against external electromagnetic interference are required, and maximum immunity against the emergence of “diaphony) among the various pairs/tender, providing electric discharge. Excellent flexibility, resistance to chemicals, humidity and UV rays. Naval cables Instrumentation are not halogen and anti-flame, not producing toxic and corrosive gases.

Maximum Conductor Temperature

CONTINUOUS SERVICE: 90°C – IEC 60092-360

SHORT CIRCUIT: 250°C

Notes

* We manufacture with other configurations:

1) The tinned copper conductor can be manufactured in class 2.

2) External cover colors: Nomenclature to be added to the end of the code: VM – Red // VD – Green // BR – White // PT – Black // AZ – Blue

We can manufacture other colors upon request.

3) Different sections and number of veins, maximum up to:

• 71 x 2 x 0.50mm² / 71 x 2 x 2.50mm²

• 71 x 3 x 0.50mm² / 71 x 3 x 2.50mm²

• 36 x 4 x 0 .50mm² / 36 x 4 x 2.50mm²

4) Material of vein insulation:

EPR

–

90

ºC

HEPR

–

90 ºC 7) Nomenclature to be added to the end of the code depending on the type of conductor:

Bare copper conductor – CN

Tinned copper conductor – SN

Naval cables instrumentation

**Innovcable reserves the right to change this catalog without prior notice.**

INNOVCABLE INNOVSHORE SHIELDED INSTRUMENTATION BFI 0.15/0.25KV (300V)

1) Conductor formed by bare or tinned electrolytic copper wires, soft temper, class 5 stranding. IEC 60228. *1.7

2) Insulation in special halogen-free compound LSOH (HF-90). *4

3) Communication conductor with 0.5mm² section, in LSOH compound (HF-90), Identification through blue insulation (only for cables with 2 or more pairs, triples or quads) – (Optional). *4

4) Individual shielding in aluminum-polyester tape, with flexible drain conductor, formed by tinned electrolytic copper wires, soft temper.

5) Cover in halogen-free polyolefin compound LSOH (SHF1), gray in color. *2.5

Identification

– External Recording:

INNOVCABLE INNOVSHORE INSTRUMENTATION BFI __mm² 0.15/0.25KV (300V) 90°C OF: XXXX/YEAR.

Of the conductors – through the colors of the insulation, being:

black and white (cables in pairs)

black, white and red (cables in bundles).

black, white, red and green (cables in blocks).*3

Identification through sequential numbering.

Applicable Specifications

Applications

Built and designed for the demanding offshore drilling environment and the naval industry.

Naval cables Instrumentation are used in fixed installations, conducting analog (4 - 20MA) and digital signals, point -to -point instrumentation, Hart ® protocol, various sensor connections and meters, conventional and electronic relay feed, in general industrial environments. Innovshore instrumentation cables BFI armored instrumentation 0.15/0.25kV (300V) are recommended for excellent levels of external electromagnetic interference protection levels, and maximum immunity against the appearance of “crosstalk” among the various pairs/tender, providing electric discharge of them. Naval cables instrumentation have excellent flexibility, resistance to chemicals, humidity and UV rays. Armed cable with galvanized steel wires. No halogen and anti-flame, not producing toxic and corrosive gases.

Maximum Conductor Temperature

CONTINUOUS SERVICE: 90°C – IEC 60092-360

SHORT CIRCUIT: 250°C

Notes

* We manufacture with other configurations:

1) The tinned copper conductor can be manufactured in class 2.

2) External cover colors: Nomenclature to be added to the end of the code: VM – Red // VD – Green // BR – White / / PT – Black // AZ – Blue // CZ – Grey.

We can manufacture other colors upon request.

3) Different sections and number of veins, maximum up to:

• 71 x 2 x 0.50mm² / 71 x 2 x 2.50mm²

• 71 x 3 x 0.50mm² / 71 x 3 x 2.50mm²

• 36 x 4 x 0 .50mm² / 36 x 4 x 2.50mm²

4) Material of vein insulation:

EPR

–

90

ºC

HEPR

–

90 ºC 7) Nomenclature to be added to the end of the code depending on the type of conductor:

Bare copper conductor – CN

Tinned copper conductor – SN

Naval cables instrumentation

**Innovcable reserves the right to change this catalog without prior notice.**

INNOVCABLE INNOVSHORE SHIELDED INSTRUMENTATION BFIC 0.15/0.25KV (300V)

1) Conductor formed by bare or tinned electrolytic copper wires, soft temper, class 5 stranding. IEC 60228. *1.7

2) Insulation in special halogen-free compound LSOH (HF-90). *4

3) Communication conductor with 0.5mm² section, in LSOH compound (HF-90), Identification through blue insulation (only for cables with 2 or more pairs, triples or quads) – (Optional). *4

4) Individual shielding in aluminum-polyester tape, with flexible drain conductor, formed by tinned electrolytic copper wires, soft temper.

5-) Collective shielding in aluminum-polyester tape, with flexible drain conductor, formed by tinned electrolytic copper wires, soft temper.

5) Cover in halogen-free polyolefin compound LSOH (SHF1), gray in color. *2.5

Identification

– External Recording:

INNOVCABLE INNOVSHORE INSTRUMENTATION BFIC __mm² 0.15/0.25KV (300V) 90°C OF: XXXX/YEAR.

Of the conductors – through the colors of the insulation, being:

black and white (cables in pairs)

black, white and red (cables in bundles).

black, white, red and green (cables in blocks).*3

Identification through sequential numbering.

Applicable Specifications

Applications

Built and designed for the demanding offshore drilling environment and the naval industry.

Naval cables Instrumentation are used in fixed installations, conducting analog (4 - 20MA) and digital signals, point -to -point instrumentation, Hart ® protocol, various sensor connections and meters, conventional and electronic relay feed, in general industrial environments. Innovshore instrumentation cables BFI INSTRUMENTATION 0.15/0.25kV (300V) are recommended for excellent levels of external electromagnetic interference protection, and maximum immunity against the appearance of “crosstalk” among the various pairs/tender, providing electric discharge of them. Excellent flexibility, resistance to chemicals, humidity and UV rays. Armed cable with galvanized steel wires. No halogen and anti-flame, not producing toxic and corrosive gases.

Maximum Conductor Temperature

CONTINUOUS SERVICE: 90°C – IEC 60092-360

SHORT CIRCUIT: 250°C

Notes

* We manufacture with other configurations:

1) The tinned copper conductor can be manufactured in class 2.

2) External cover colors: Nomenclature to be added to the end of the code: VM – Red // VD – Green // BR – White / / PT – Black // AZ – Blue // CZ – Grey.

We can manufacture other colors upon request.

3) Different sections and number of veins, maximum up to:

• 71 x 2 x 0.50mm² / 71 x 2 x 2.50mm²

• 71 x 3 x 0.50mm² / 71 x 3 x 2.50mm²

• 36 x 4 x 0 .50mm² / 36 x 4 x 2.50mm²

4) Material of vein insulation:

EPR

–

90

ºC

HEPR

–

90 ºC 7) Nomenclature to be added to the end of the code depending on the type of conductor:

Bare copper conductor – CN

Tinned copper conductor – SN

Naval cables instrumentation

**Innovcable reserves the right to change this catalog without prior notice.**

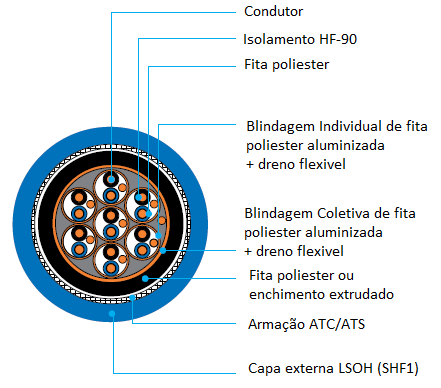

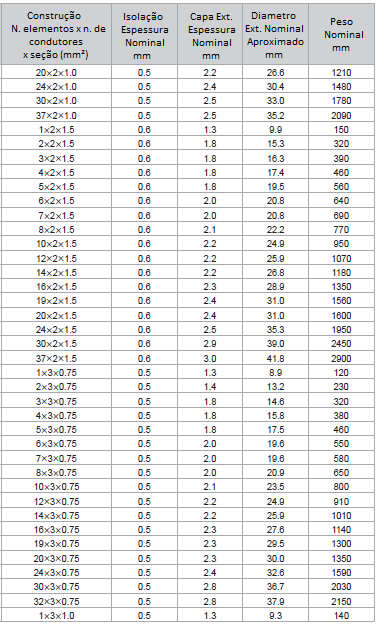

INNOVCABLE INNOVSHORE ARMED INSTRUMENTATION ATC/ATS 0.15/0.25KV (300V)

1) Conductor formed by bare or tinned electrolytic copper wires, soft temper, class 5 stranding. IEC 60228. *1.7

2) Insulation in special halogen-free compound LSOH (HF-90). *4

3) Communication conductor with 0.5mm² section, in LSOH compound (HF-90), Identification through blue insulation (only for cables with 2 or more pairs, triples or quads) – (Optional). *4

5) Polyester tape.

6) Frame: Braid of bare copper wires (ATC) or tinned copper wires (ATS) with coverage >90% *8

7) Cover in halogen-free polyolefin compound LSOH (SHF1), gray in color. *2.5

Identification

– External Recording:

INNOVCABLE INNOVSHORE INSTRUMENTATION ATC/ATS __mm² 0.15/0.25KV (300V) 90°C OF: XXXX/YEAR.

Of the conductors – through the colors of the insulation, being:

black and white (cables in pairs)

black, white and red (cables in bundles).

black, white, red and green (cables in blocks).*3

Identification through sequential numbering.

Applicable Specifications

Applications

Built and designed for the demanding offshore drilling environment and the naval industry.

Armed cable prove protection where impacts are required.

Naval cables Instrumentation are used in fixed installations, conducting analog (4 - 20MA) and digital signals, point -to -point instrumentation, Hart ® protocol, various sensor connections and meters, conventional and electronic relay feed, in general industrial environments. Innovshore instrumentation cables armed instrumentation ATC/ATS 0.15/0.25kV (300V) have excellent flexibility, resistance to chemicals, humidity and UV rays. Armed cable in naked copper wires (ATC) or tinned copper wires (ATS). No halogen and anti-flame, not producing toxic and corrosive gases.

Maximum Conductor Temperature

CONTINUOUS SERVICE: 90°C – IEC 60092-360

SHORT CIRCUIT: 250°C

Notes

* We manufacture with other configurations:

1) The tinned copper conductor can be manufactured in class 2.

2) External cover colors: Nomenclature to be added to the end of the code: VM – Red // VD – Green // BR – White / / PT – Black // AZ – Blue // CZ – Grey.

We can manufacture other colors upon request.

3) Different sections and number of veins, maximum up to:

• 71 x 2 x 0.50mm² / 71 x 2 x 2.50mm²

• 71 x 3 x 0.50mm² / 71 x 3 x 2.50mm²

• 36 x 4 x 0 .50mm² / 36 x 4 x 2.50mm²

4) Material of vein insulation:

EPR

–

90

ºC

HEPR

–

90 ºC 7) Nomenclature to be added to the end of the code depending on the type of conductor:

Bare copper conductor – CN

Tinned copper conductor – SN

8) Types of frames:

ATC – Bare copper wire braid frame

ATS – Braid frame of tinned copper wire

Naval cables instrumentation

**Innovcable reserves the right to change this catalog without prior notice.**

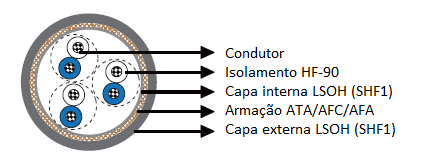

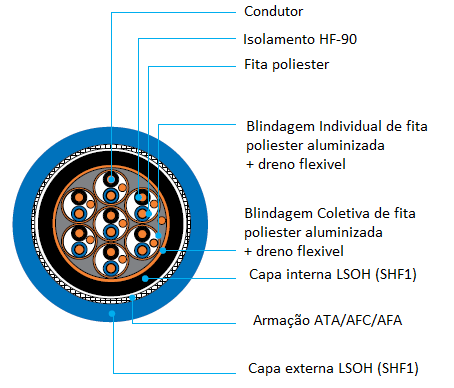

INNOVCABLE INNOVSHORE ARMED INSTRUMENTATION ATA/AFC/AFA 0.15/0.25KV (300V)

1) Conductor formed by bare or tinned electrolytic copper wires, soft temper, class 5 stranding. IEC 60228. *1.7

2) Insulation in special halogen-free compound LSOH (HF-90). *4

3) Communication conductor with 0.5mm² section, in LSOH compound (HF-90), Identification through blue insulation (only for cables with 2 or more pairs, triples or quads) – (Optional). *4

5) Inner cover in halogen-free polyolefin compound LSOH (SHF1). *5

6) Frame: Braid of galvanized steel wires (ATA) with coverage >90%; copper tape (AFC) or galvanized steel tape (AFA) applied with overlap. *8

7) Cover in halogen-free polyolefin compound LSOH (SHF1), gray in color. *2.5

Identification

– External Recording:

INNOVCABLE INNOVSHORE INSTRUMENTATION ATA/AFC/AFA __mm² 0.15/0.25KV (300V) 90°C OF: XXXX/YEAR.

Of the conductors – through the colors of the insulation, being:

black and white (cables in pairs)

black, white and red (cables in bundles).

black, white, red and green (cables in blocks).*3

Identification through sequential numbering.

Applicable Specifications

Applications

Built and designed for the demanding offshore drilling environment and the naval industry.

Armed cable prove protection where it is required, against impacts.

Naval cables Instrumentation used in fixed facilities, conducting analog (4 - 20MA) and digital signals, point -to -point instrumentation, Hart ® protocol, various sensor connections and meters, conventional and electronic relay feed, in general industrial environments. Innovshore instrumentation cables ATA/AFC/AFA/AFA 0.15/0.25kV (300V) have excellent flexibility, resistance to chemicals, humidity and UV rays. Armed cable with galvanized steel wires. No halogen and anti-flame, not producing toxic and corrosive gases.

Maximum Conductor Temperature

CONTINUOUS SERVICE: 90°C – IEC 60092-360

SHORT CIRCUIT: 250°C

Notes

* We manufacture with other configurations:

1) The tinned copper conductor can be manufactured in class 2.

2) External cover colors: Nomenclature to be added to the end of the code: VM – Red // VD – Green // BR – White / / PT – Black // AZ – Blue // CZ – Grey.

We can manufacture other colors upon request.

3) Different sections and number of veins, maximum up to:

• 71 x 2 x 0.50mm² / 71 x 2 x 2.50mm²

• 71 x 3 x 0.50mm² / 71 x 3 x 2.50mm²

• 36 x 4 x 0 .50mm² / 36 x 4 x 2.50mm²

4) Material of vein insulation:

EPR

–

90

ºC

HEPR

–

90 ºC 7) Nomenclature to be added to the end of the code depending on the type of conductor:

Bare copper conductor – CN

Tinned copper conductor – SN

8) Types of frames:

ATA – Braided frame made of galvanized steel wires

AFC – Ribbon frame copper

AFA – Galvanized steel strip frame

**Innovcable reserves the right to change this catalog without prior notice.**

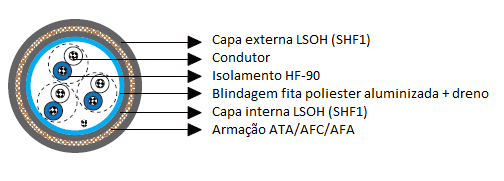

INNOVCABLE INNOVSHORE INSTRUMENTATION ARMED/SHIELDED ATA/AFC/AFA BF 0.15/0.25KV (300V)

1) Conductor formed by bare or tinned electrolytic copper wires, soft temper, class 5 stranding. IEC 60228. *1.7

2) Insulation in special halogen-free compound LSOH (HF-90). *4

3) Communication conductor with 0.5mm² section, in LSOH compound (HF-90), Identification through blue insulation (only for cables with 2 or more pairs, triples or quads) – (Optional). *4

4) Collective shielding in aluminum-polyester tape, with flexible drain conductor, formed by tinned electrolytic copper wires, soft temper.

5) Inner cover made of halogen-free polyolefin compound (SHF1). *5

6) Frame: Galvanized steel wire braid (ATA) with coverage >90%; copper tape (AFC) or galvanized steel tape (AFA) applied with overlap. *8

7) Cover in halogen-free polyolefin compound LSOH (SHF1), gray in color. *2.5

Identification

– External Recording:

INNOVCABLE INNOVSHORE INSTRUMENTATION ATA/AFC/AFA BF __mm² 0.15/0.25KV (300V) 90°C OF: XXXX/YEAR.

Of the conductors – through the colors of the insulation, being:

black and white (cables in pairs)

black, white and red (cables in bundles).

black, white, red and green (cables in blocks).*3

Identification through sequential numbering.

Applicable Specifications

Applications

Built and designed for the demanding offshore drilling environment and the naval industry.

Armed cable prove protection where impacts are required.

Naval cables Instrumentation are used in fixed installations, conducting analog (4 - 20MA) and digital signals, point -to -point instrumentation, Hart ® protocol, various sensor connections and meters, conventional and electronic relay feed, in general industrial environments. Innovshore instrumentation cables armed/armored instrumentation/ATA/AFC/AFA BF 0.15/0.25kV (300V) are recommended for excellent levels of protection against external electromagnetic interference, and maximum immunity against the appearance of “CrossStalk” (diaphony) among the various pairs/terns, providing electric discharge. Excellent flexibility, resistance to chemicals, humidity and UV rays. Armed cable with galvanized steel wires. No halogen and anti-flame, not producing toxic and corrosive gases.

Maximum Conductor Temperature

CONTINUOUS SERVICE: 90°C – IEC 60092-360

SHORT CIRCUIT: 250°C

Notes

* We manufacture with other configurations:

1) The tinned copper conductor can be manufactured in class 2.

2) External cover colors: Nomenclature to be added to the end of the code: VM – Red // VD – Green // BR – White / / PT – Black // AZ – Blue // CZ – Grey.

We can manufacture other colors upon request.

3) Different sections and number of veins, maximum up to:

• 71 x 2 x 0.50mm² / 71 x 2 x 2.50mm²

• 71 x 3 x 0.50mm² / 71 x 3 x 2.50mm²

• 36 x 4 x 0 .50mm² / 36 x 4 x 2.50mm²

4) Material of vein insulation:

EPR

–

90

ºC

HEPR

–

90 ºC 7) Nomenclature to be added to the end of the code depending on the type of conductor:

Bare copper conductor – CN

Tinned copper conductor – SN

8) Types of frames:

ATA – Braided frame made of galvanized steel wires

AFC – Ribbon frame copper

AFA – Galvanized steel strip frame

Naval cables instrumentation

**Innovcable reserves the right to change this catalog without prior notice.**

INNOVCABLE INNOVSHORE INSTRUMENTATION ARMED/SHIELDED ATA/AFC/AFA BFI 0.15/0.25KV (300V)

1) Conductor formed by bare or tinned electrolytic copper wires, soft temper, class 5 stranding. IEC 60228. *1.7

2) Insulation in special halogen-free compound LSOH (HF-90). *4

3) Communication conductor with 0.5mm² section, in LSOH compound (HF-90), Identification through blue insulation (only for cables with 2 or more pairs, triples or quads) – (Optional). *4

4) Individual shielding in aluminum-polyester tape, with flexible drain conductor, formed by tinned electrolytic copper wires, soft temper.

5) Inner cover made of halogen-free polyolefin compound (SHF1). *5

6) Frame: Galvanized steel wire braid (ATA) with coverage >90%; copper tape (AFC) or galvanized steel tape (AFA) applied with overlap. *8

7) Cover in halogen-free polyolefin compound LSOH (SHF1), gray in color. *2.5

Identification

– External Recording:

INNOVCABLE INNOVSHORE INSTRUMENTATION ATA/AFC/AFA BFI __mm² 0.15/0.25KV (300V) 90°C OF: XXXX/YEAR.

Of the conductors – through the colors of the insulation, being:

black and white (cables in pairs)

black, white and red (cables in bundles).

black, white, red and green (cables in blocks).*3

Identification through sequential numbering.

Applicable Specifications

Applications

Built and designed for the demanding offshore drilling environment and the naval industry.

Armed cable prove protection where impacts are required.

Naval cables Instrumentation are used in fixed installations, conducting analog (4 - 20MA) and digital signals, point -to -point instrumentation, Hart ® protocol, various sensor connections and meters, conventional and electronic relay feed, in general industrial environments. Innovshore instrumentation cables armed/armored instrumentation/AFC/AFC/AFA BFI 0.15/0.25kV (300V) are recommended for excellent levels of protection against external electromagnetic interference, and maximum immunity against the appearance of “CrossStalk” (diaphony) among the various pairs/terns, providing electric discharge. Excellent flexibility, resistance to chemicals, humidity and UV rays. Armed cable with galvanized steel wires. No halogen and anti-flame, not producing toxic and corrosive gases.

Maximum Conductor Temperature

CONTINUOUS SERVICE: 90°C – IEC 60092-360

SHORT CIRCUIT: 250°C

Notes

* We manufacture with other configurations:

1) The tinned copper conductor can be manufactured in class 2.

2) External cover colors: Nomenclature to be added to the end of the code: VM – Red // VD – Green // BR – White / / PT – Black // AZ – Blue // CZ – Grey.

We can manufacture other colors upon request.

3) Different sections and number of veins, maximum up to:

• 71 x 2 x 0.50mm² / 71 x 2 x 2.50mm²

• 71 x 3 x 0.50mm² / 71 x 3 x 2.50mm²

• 36 x 4 x 0 .50mm² / 36 x 4 x 2.50mm²

4) Material of vein insulation:

EPR

–

90

ºC

HEPR

–

90 ºC 7) Nomenclature to be added to the end of the code depending on the type of conductor:

Bare copper conductor – CN

Tinned copper conductor – SN

8) Types of frames:

ATA – Braided frame made of galvanized steel wires

AFC – Ribbon frame copper

AFA – Galvanized steel strip frame

Naval cables instrumentation

**Innovcable reserves the right to change this catalog without prior notice.**

INNOVCABLE INNOVSHORE INSTRUMENTATION ARMED/SHIELDED ATA/AFC/AFA BFIC 0.15/0.25KV (300V)

1) Conductor formed by bare or tinned electrolytic copper wires, soft temper, class 5 stranding. IEC 60228. *1.7

2) Insulation in special halogen-free compound LSOH (HF-90). *4

3) Communication conductor with 0.5mm² section, in LSOH compound (HF-90), Identification through blue insulation (only for cables with 2 or more pairs, triples or quads) – (Optional). *4

4) Individual shielding in aluminum-polyester tape, with flexible drain conductor, formed by tinned electrolytic copper wires, soft temper.

5) Collective shielding in aluminum-polyester tape, with flexible drain conductor, formed by tinned electrolytic copper wires, soft temper.

6) Inner cover made of halogen-free polyolefin compound (SHF1). *5

7) Frame: Galvanized steel wire braid (ATA) with coverage >90%; copper tape (AFC) or galvanized steel tape (AFA) applied with overlap. *8

8) Cover in halogen-free polyolefin compound LSOH (SHF1), gray in color. *2.5

Identification

– External Recording:

INNOVCABLE INNOVSHORE INSTRUMENTATION ATA/AFC/AFA BFIC __mm² 0.15/0.25KV (300V) 90°C OF: XXXX/YEAR.

Of the conductors – through the colors of the insulation, being:

black and white (cables in pairs)

black, white and red (cables in bundles).

black, white, red and green (cables in blocks).*3

Identification through sequential numbering.

Applicable Specifications

Applications

Built and designed for the demanding offshore drilling environment and the naval industry.

Armed cable prove protection where impacts are required.

Naval cables Instrumentation are used in fixed installations, conducting analog (4 - 20MA) and digital signals, point -to -point instrumentation, Hart ® protocol, various sensor connections and meters, conventional and electronic relay feed, in general industrial environments. Innovshore instrumentation cables armed/armored instrumentation/AFC/AFC/AFA BFI 0.15/0.25kV (300V) are recommended for excellent levels of protection against external electromagnetic interference, and maximum immunity against the appearance of “CrossStalk” (diaphony) among the various pairs/terns, providing electric discharge. Excellent flexibility, resistance to chemicals, humidity and UV rays. Armed cable with galvanized steel wires. No halogen and anti-flame, not producing toxic and corrosive gases.

Maximum Conductor Temperature

CONTINUOUS SERVICE: 90°C – IEC 60092-360

SHORT CIRCUIT: 250°C

Notes

* We manufacture with other configurations:

1) The tinned copper conductor can be manufactured in class 2.

2) External cover colors: Nomenclature to be added to the end of the code: VM – Red // VD – Green // BR – White / / PT – Black // AZ – Blue // CZ – Grey.

We can manufacture other colors upon request.

3) Different sections and number of veins, maximum up to:

• 71 x 2 x 0.50mm² / 71 x 2 x 2.50mm²

• 71 x 3 x 0.50mm² / 71 x 3 x 2.50mm²

• 36 x 4 x 0 .50mm² / 36 x 4 x 2.50mm²

4) Material of vein insulation:

EPR

–

90

ºC

HEPR

–

90 ºC 7) Nomenclature to be added to the end of the code depending on the type of conductor:

Bare copper conductor – CN

Tinned copper conductor – SN

8) Types of frames:

ATA – Braided frame made of galvanized steel wires

AFC – Ribbon frame copper

AFA – Galvanized steel strip frame

Naval cables instrumentation

**Innovcable reserves the right to change this catalog without prior notice.**

INNOVCABLE INNOVSHORE INSTRUMENTATION ARMED/ARMORED ATC/ATS BF 0.15/0.25KV (300V)

1) Conductor formed by bare or tinned electrolytic copper wires, soft temper, class 5 stranding. IEC 60228. *1.7

2) Insulation in special halogen-free compound LSOH (HF-90). *4

3) Communication conductor with 0.5mm² section, in LSOH compound (HF-90), Identification through blue insulation (only for cables with 2 or more pairs, triples or quads) – (Optional). *4

4) Collective shielding in aluminum-polyester tape, with flexible drain conductor, formed by tinned electrolytic copper wires, soft temper.

5) Polyester tape / extruded filling.

6) Frame: Braid of bare copper wires (ATC) or tinned copper wires (ATS) with coverage >90% *8

7) Cover in halogen-free polyolefin compound LSOH (SHF1), gray in color. *2.5

Identification

– External Recording:

INNOVCABLE INNOVSHORE INSTRUMENTATION ATC/ATS BF __mm² 0.15/0.25KV (300V) 90°C OF: XXXX/YEAR.

Of the conductors – through the colors of the insulation, being:

black and white (cables in pairs)

black, white and red (cables in bundles).

black, white, red and green (cables in blocks).*3

Identification through sequential numbering.

Applicable Specifications

Applications

Built and designed for the demanding offshore drilling environment and the naval industry.

Armed cable prove protection where impacts are required.

Naval cables Instrumentation are used in fixed installations, conducting analog (4 - 20MA) and digital signals, point -to -point instrumentation, Hart ® protocol, various sensor connections and meters, conventional and electronic relay feed, in general industrial environments. Innovshore instrumentation cables armed/armored instrumentation ATC/ATS BF 0.15/0.25kV (300V) are recommended for excellent levels of protection against external electromagnetic interference, and maximum immunity against the appearance of “crosstalk” (diaphony) among the various pairs/tender, providing electrical discharge of them. Excellent flexibility, resistance to chemicals, humidity and UV rays. Armed cable with galvanized steel wires. No halogen and anti-flame, not producing toxic and corrosive gases.

Maximum Conductor Temperature

CONTINUOUS SERVICE: 90°C – IEC 60092-360

SHORT CIRCUIT: 250°C

Notes

* We manufacture with other configurations:

1) The tinned copper conductor can be manufactured in class 2.

2) External cover colors: Nomenclature to be added to the end of the code: VM – Red // VD – Green // BR – White / / PT – Black // AZ – Blue // CZ – Grey.

We can manufacture other colors upon request.

3) Different sections and number of veins, maximum up to:

• 71 x 2 x 0.50mm² / 71 x 2 x 2.50mm²

• 71 x 3 x 0.50mm² / 71 x 3 x 2.50mm²

• 36 x 4 x 0 .50mm² / 36 x 4 x 2.50mm²

4) Material of vein insulation:

EPR

–

90

ºC

HEPR

–

90 ºC 7) Nomenclature to be added to the end of the code depending on the type of conductor:

Bare copper conductor – CN

Tinned copper conductor – SN

8) Types of frames:

ATC – Bare copper wire braid frame

ATS – Braid frame of tinned copper wire

**Innovcable reserves the right to change this catalog without prior notice.**

INNOVCABLE INNOVSHORE ARMED/ARMORED INSTRUMENTATION ATC/ATS BFI 0.15/0.25KV (300V)

1) Conductor formed by bare or tinned electrolytic copper wires, soft temper, class 5 stranding. IEC 60228. *1.7

2) Insulation in special halogen-free compound LSOH (HF-90). *4

3) Communication conductor with 0.5mm² section, in LSOH compound (HF-90), Identification through blue insulation (only for cables with 2 or more pairs, triples or quads) – (Optional). *4

4) Individual shielding in aluminum-polyester tape, with flexible drain conductor, formed by tinned electrolytic copper wires, soft temper.

5) Polyester tape.

6) Frame: Braid of bare copper (ATC) or tinned copper (ATS) wires with coverage >90%.* 8

7) Cover in halogen-free polyolefin compound LSOH (SHF1), gray in color. *2.5

Identification

– External Recording:

INNOVCABLE INNOVSHORE INSTRUMENTATION ATC/ATS BFI __mm² 0.15/0.25KV (300V) 90°C OF: XXXX/YEAR.

Of the conductors – through the colors of the insulation, being:

black and white (cables in pairs)

black, white and red (cables in bundles).

black, white, red and green (cables in blocks).*3

Identification through sequential numbering.

Applicable Specifications

Applications

Built and designed for the demanding offshore drilling environment and the naval industry.

Naval cables Instrumentation are used in fixed installations, conducting analog (4 - 20MA) and digital signals, point -to -point instrumentation, Hart ® protocol, various sensor connections and meters, conventional and electronic relay feed, in general industrial environments. Innovshore instrumentation cables armed/armored instrumentation ATC/ATS BFI 0.15/0.25kV (300V) are recommended for excellent levels of protection against external electromagnetic interference, and maximum immunity against the onset of “crosstalk” (diaphony) among the various pairs/tender, providing electrical discharge. Excellent flexibility, resistance to chemicals, humidity and UV rays. Armed cable with galvanized steel wires. No halogen and anti-flame, not producing toxic and corrosive gases.

Maximum Conductor Temperature

CONTINUOUS SERVICE: 90°C – IEC 60092-360

SHORT CIRCUIT: 250°C

Notes

* We manufacture with other configurations:

1) The tinned copper conductor can be manufactured in class 2.

2) External cover colors: Nomenclature to be added to the end of the code: VM – Red // VD – Green // BR – White / / PT – Black // AZ – Blue // CZ – Grey.

We can manufacture other colors upon request.

3) Different sections and number of veins, maximum up to:

• 71 x 2 x 0.50mm² / 71 x 2 x 2.50mm²

• 71 x 3 x 0.50mm² / 71 x 3 x 2.50mm²

• 36 x 4 x 0 .50mm² / 36 x 4 x 2.50mm²

4) Material of vein insulation:

EPR

–

90

ºC

HEPR

–

90 ºC 7) Nomenclature to be added to the end of the code depending on the type of conductor:

Bare copper conductor – CN

Tinned copper conductor – SN

8) Types of frames:

ATS – Tinned copper wire braid frame

ATC – Braid frame of bare copper wires

Naval cables instrumentation

**Innovcable reserves the right to change this catalog without prior notice.**

INNOVCABLE INNOVSHORE INSTRUMENTATION ARMED/ARMORED ATC/ATS BFIC 0.15/0.25KV (300V)

1) Conductor formed by bare or tinned electrolytic copper wires, soft temper, class 5 stranding. IEC 60228. *1.7

2) Insulation in special halogen-free compound LSOH (HF-90). *4

3) Communication conductor with 0.5mm² section, in LSOH compound (HF-90), Identification through blue insulation (only for cables with 2 or more pairs, triples or quads) – (Optional). *4

4) Individual shielding in aluminum-polyester tape, with flexible drain conductor, formed by tinned electrolytic copper wires, soft temper.

5) Collective shielding in aluminum-polyester tape, with flexible drain conductor, formed by tinned electrolytic copper wires, soft temper.

6) Polyester tape.

7) Frame: Braid of bare copper (ATC) or tinned copper (ATS) wires with coverage >90%.* 8

8) Cover in halogen-free polyolefin compound LSOH (SHF1), gray in color. *2.5

Identification

– External Recording:

INNOVCABLE INNOVSHORE INSTRUMENTATION ATC/ATS BFIC __mm² 0.15/0.25KV (300V) 90°C OF: XXXX/YEAR.

Of the conductors – through the colors of the insulation, being:

black and white (cables in pairs)

black, white and red (cables in bundles).

black, white, red and green (cables in blocks).*3

Identification through sequential numbering.

Applicable Specifications

Applications

Built and designed for the demanding offshore drilling environment and the naval industry.

Naval cables Instrumentation are used in fixed installations, conducting analog (4 - 20MA) and digital signals, point -to -point instrumentation, Hart ® protocol, various sensor connections and meters, conventional and electronic relay feed, in general industrial environments. Innovshore instrumentation cables armed/armored instrumentation ATC/ATS BFI 0.15/0.25kV (300V) are recommended for excellent levels of protection against external electromagnetic interference, and maximum immunity against the onset of “crosstalk” (diaphony), providing the electrical discharge of them. Excellent flexibility, resistance to chemicals, humidity and UV rays. Armed cable with galvanized steel wires. No halogen and anti-flame, not producing toxic and corrosive gases.

Maximum Conductor Temperature

CONTINUOUS SERVICE: 90°C – IEC 60092-360

SHORT CIRCUIT: 250°C

Notes

* We manufacture with other configurations:

1) The tinned copper conductor can be manufactured in class 2.

2) External cover colors: Nomenclature to be added to the end of the code: VM – Red // VD – Green // BR – White / / PT – Black // AZ – Blue // CZ – Grey.

We can manufacture other colors upon request.

3) Different sections and number of veins, maximum up to:

• 71 x 2 x 0.50mm² / 71 x 2 x 2.50mm²

• 71 x 3 x 0.50mm² / 71 x 3 x 2.50mm²

• 36 x 4 x 0 .50mm² / 36 x 4 x 2.50mm²

4) Material of vein insulation:

EPR

–

90

ºC

HEPR

–

90 ºC 7) Nomenclature to be added to the end of the code depending on the type of conductor:

Bare copper conductor – CN

Tinned copper conductor – SN

8) Types of frames:

ATS – Tinned copper wire braid frame

ATC – Braid frame of bare copper wires

Naval cables instrumentation

**Innovcable reserves the right to change this catalog without prior notice.**

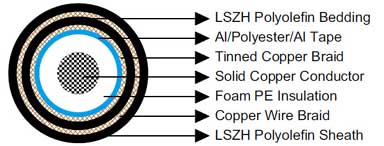

INNOVCABLE INNOVSHORE NAVAL COAXIAL RG6 ARMED

Conductors: Ø=0.72±0.025mm

Dielectric: PE Ø=4.70±0.10mm

Shield 1: Al / polyester / Al. 100% covered

Shield 2: Tinned copper braid 144 x 0.16mm

Intermediate cover: SHF1 LSZH, low emission smoke and toxic gases

Armor: galvanized steel wire mesh. 144 x0.16mm

External cover: SHF1 LSZH, low emission of smoke and toxic gases in black

ELECTRICAL CHARACTERISTICS:

Impedance: Ω75+/-5

Nominal Attenuation@100MHz dB/100m 6.9

Nominal Attenuation@200MHz dB/100m 9.0

Nominal Attenuation@300MHz dB/100m 11.8

Nominal Attenuation@400MHz dB/100m 13.1

Nominal Attenuation@500MHz dB/100m 15.4

Nominal Attenuation@900MHz dB/100m 21.5

Nominal Attenuation@1700MHz dB/100m 29.4

Capacitance pF/m 53.5

Propagation speed % 83

Conductor DCR Ω/km 21.4

Shielding DCR Ω/km 7.5

Inductance μH/m 0.32

Delay time ns/m 4

THERMAL AND MECHANICAL CHARACTERISTICS:

Radius of curvature: 15×OD .

Final diameter: 11.2mm

Identification

INNOVCABLE COAXIAL RG6 ARMORED – IEC 60332-3-22

Applicable Specifications

Applications

75Ω coaxial cable suitable for installation on board ships and other inland marine environments.

Maximum Conductor Temperature

-30℃ ~ +75℃.

Notes

**Innovcable reserves the right to change this catalog without prior notice.**