Naval Cables – NEK-606/IEC – SHF2 Mud Resistance

Power, control and lighting cables – Fire resistance IEC 60331 – SHF2 Mud resistance

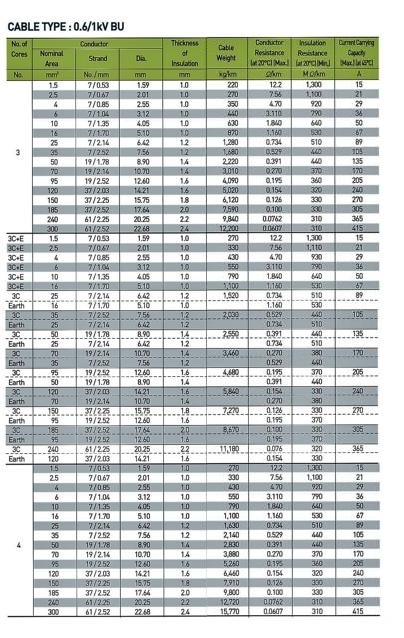

INNOVCABLE Power, Control and Lighting 0.6/1(1.2)kV BU – P17 – SHF2 Resistance – IEC 60331

1) Conductor formed by tinned electrolytic copper wires, soft temper, class 5 stranding, in accordance with IEC 60228. *1

2-) Application of Mica ceramic and insulation of conductors in special halogen-free compound LSOH – IEC 60331 ( Code B)

3) Insulated conductors cabled together, non-hygroscopic and flame retardant filaments can be used flame in the conductor construction and tapes can be applied over the conductors.

4) Final cover in halogen-free polyolefin compound LSOH (SHF2), black. (U Code)

Identification

A-) Number of conductors (Without Earth conductor G)

1C: Single conductor – Black or White

2C: Two conductors – White, Black

3C: Three conductors – White, Black, Red

4C: Four conductors – White, Black, Red and Blue

5C or more: Five conductors or more – Sequentially numbered black or white conductors.

B-) Number of conductors (With Earth conductor G)

2C +E: Three conductors – White, Black, Green

3C +E: Four conductors – White, Black, Red and Green

4C +E: Five conductors -White, Black, Red , Blue and Green

6C or more: Six conductors or more – Black or white conductors numbered sequentially + green track

Engraving on the outer cover (example): “ano” Innovcable 01 BU 0.6/1kV P17 1 x 70 mm2 IEC 60331-21 IEC 60332-3-22

Applicable Specifications

Applications

Naval cables for fixed installations for power, control and lighting in EX environments (Zone 0, 1 and 2) and safe areas (SHF2). Meets resistance requirements as per NEK TS 606 (SHF2). Cables have double layers, single cables are used as battery cables. Cable with IEC 60331 Fire Resistance.

Maximum Conductor Temperature

90°C

Notes

1) The tinned copper conductor can be manufactured in class 2.

2) Operating voltage: 0.6/1(1.2)kV

**Innovcable reserves the right to change this catalog without prior notice.**

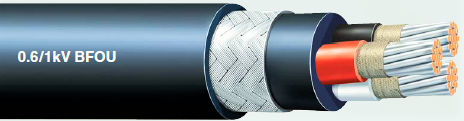

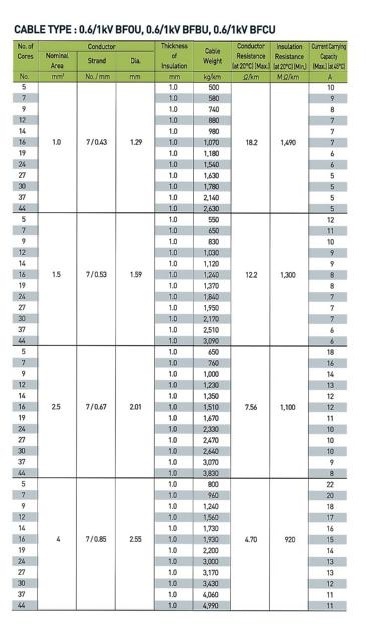

INNOVCABLE Power, Control and Lighting 0.6/1(1.2)kV BFOU, BFBU, BFCU – P5 and P5/P12 – SHF2 Resistance – IEC 60331

1) Conductor formed by tinned electrolytic copper wires, soft temper, class 5 stranding, in accordance with IEC 60228. *1

2-) Application of Mica ceramic and insulation of conductors in special halogen-free compound LSOH – IEC 60331 ( Code B)

3) Insulated conductors cabled together, non-hygroscopic and flame retardant filaments can be used flame in the conductor construction and tapes can be applied over the conductors.

4) Inner cover in halogen-free polyolefin compound LSOH – (Code F)

5) Frame: *2

– Mesh of tinned copper wires (Code 0)

– Mesh of bronze wires (Code B)

– Mesh of galvanized steel wires (Code C)

6) Final cover in halogen-free polyolefin compound LSOH (SHF2), black. (U Code)

Identification

A-) Number of conductors (Without Earth conductor G)

1C: Single conductor – Black or White

2C: Two conductors – White, Black

3C: Three conductors – White, Black, Red

4C: Four conductors – White, Black, Red and Blue

5C or more: Five conductors or more – Sequentially numbered black or white conductors.

B-) Number of conductors (With Earth conductor G)

2C +E: Three conductors – White, Black, Green

3C +E: Four conductors – White, Black, Red and Green

4C +E: Five conductors -White, Black, Red , Blue and Green

6C or more: Six conductors or more – Black or white conductors numbered sequentially + green track

Engraving on the outer cover (example): “ano” Innovcable 01 BFOU 0.6/1KV P5/P12 3 x 2.5 mm2 – FLAME IEC 60331-1 or IEC 60331-2 IEC 60331-21 IEC 60332-3-22

Applicable Specifications

Applications

Naval cables for fixed installations for power, control and lighting in EX environments (Zone 0, 1 and 2) and safe areas (SHF2). Meets resistance requirements as per NEK TS 606 (SHF2). Cable with IEC 60331 Fire Resistance.

Maximum Conductor Temperature

90°C

Notes

1) The tinned copper conductor can be manufactured in class 2.

2) Separating tape can be applied before/after the frame.

3) Operating voltage: 0.6/1(1.2)kV

**Innovcable reserves the right to change this catalog without prior notice.**

INNOVCABLE Frequency Inverter – 0.6/1kV(1.8/3kV) BFOU(VFD) – SHF2 Resistance – IEC 60331

1) Conductor formed by tinned electrolytic copper wires, soft temper, class 5 stranding, in accordance with IEC 60228. *1

2-) Application of Mica ceramic and insulation of conductors in special halogen-free compound LSOH – IEC 60331 ( Code B)

3) Insulated conductors cabled together, non-hygroscopic and flame retardant filaments can be used flame in the conductor construction and tapes can be applied over the conductors.

4) Inner cover in halogen-free polyolefin compound LSOH – (Code F)

5) Application of copper tape.

6) Frame: *2

– Mesh of tinned copper wires (Code 0)

– Mesh of bronze wires (Code B)

– Mesh of galvanized steel wires (Code C)

7) Final cover in halogen-free polyolefin compound LSOH ( SHF2), in black. (U Code)

Identification

Conductor colors: Black, White, Red

Ground conductor colors: green.

EXTERNAL RECORDING (example): INNOVCABLE 01 BFOU – VFD 0.6/1(1.8/3)kV 3X95 + 3×16 mm² FLAME IEC 60331-1 or IEC 60331-2 IEC 60331-21, IEC 60332-3- 22

Applicable Specifications

Applications

Special cable for Motors and Frequency Inverters / Azimuth Motors up to 1 kV. Suitable for voltage spikes up to 3600V. Armored cable for fixed installations on ships and offshore units. It can be installed and operated both indoors and outdoors. NEK 606. For environments requiring flame protection in accordance with IEC 60331.

Maximum Conductor Temperature

90°C

Notes

1) The tinned copper conductor can be manufactured in class 2.

2) Separator tape can be applied before/after the frame.

3) Operating voltage: 0.6/1kV (1.8/3kV)

**Innovcable reserves the right to change this catalog without prior notice.**