KNOWLEDGE ACADEMY

APPLICATION AND INSTALLATION OF MOVING CABLES – CRANES, CRANES, FESTOONS, ELEVATORS, CRANE BEATS…

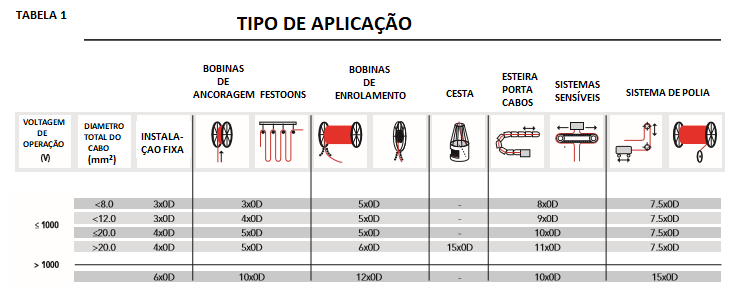

CURVATURE RADIUS

These are the minimum bending radii for use in different applications. These recommendations must be strictly followed and the curvature calculated correctly in order to obtain the best result and durability of the cable. Never increase the minimum radius of curvature stipulated because it causes stretching and internal twisting, compromising the useful life. The frequency of movement must also be taken into account, because if there is low demand, the minimum radius of curvature may be tightened (slow or few movements)

The table above provides the recommended minimum bend radii for different cable uses. Compliance with these recommendations and an accurate calculation of the bending radius are important as one of the most important reliability factors. Increasing the minimum bending radius has a more than proportional effect on the useful life of a cable because it causes stretching and internal twists due to the increase in mechanical stress on the conductors.

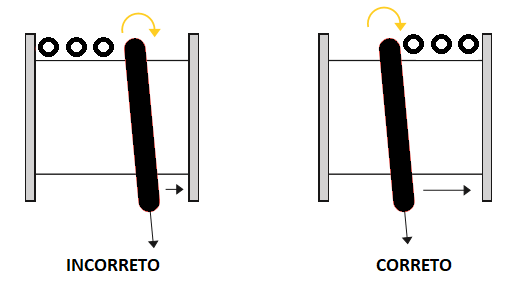

INSTALLATION - CABLE GUIDE ANALYSIS

- Always use guides that provide the best bending radius with the lowest possible deflection.

- Always keep the guides aligned to avoid twisting.

A one-way system appears to be more economically advantageous. However, a considerable increase in cable life is obtained if a two-way guide is used: This does not occur if the winding system is fed at the end, remaining in contact with the cable, regardless of the direction of movement of the machine.

Avoid any abrupt changes in the bending radius, otherwise this could lead to cable breakage.

Always use voltage protection systems when guiding the cable. Working voltages and protection devices must be defined according to parameters defined for each section of the cable.

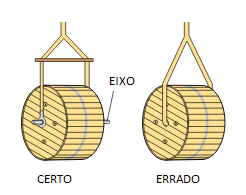

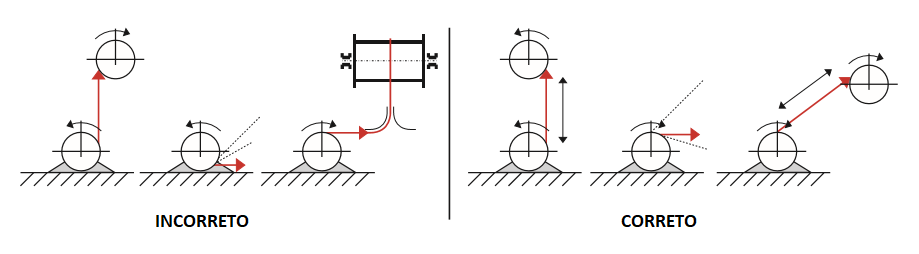

INSTALLATION - PULLEY ANALYSIS

INCORRECT APPLICATION ON THE PULLEY: Effect induces twisting in the cable due to the rolling effect, reducing its useful life.

CORRECT APPLICATION ON THE PULLEY: Way that minimizes the twist applied to the cable.

INSTALLATION - CHANGING DIRECTION

INSTALLATION - ANCHORAGE SYSTEM

The most common mobile anchor points are cable grips. The load voltage must be distributed along the entire length of the cable between 20 to 25 x its total diameter. In order to maintain operational movements, leave a surplus of cables before entering the terminal box. When the center point inner fitting is installed, the vertical distance between the inlet mouth and the crane guide should not be less than 15 times the total cable diameter or 1m, whichever is greater. At least 2 turns of cable must be made around the fixed relief drum to ensure sufficient contact area for adequate stress to occur.

Stress dynamics in the cable can lead to premature failure, especially in high-speed applications. To minimize this, you can use several solutions, but pay attention to the speed reduction device. It is interesting to apply this system to your spool movement project, reducing the speed before reaching the central point, and then re-accelerating after passing the central point and the direction of the spool of rotation has been reversed.

- Cable support

- Entrance mouth

- Anti-stress bearing drum*

- Cable wound twice on anti-stress winding drum

- Power cord

- Terminal box

- Cable Tie

*(For Medium Voltage cables= 10 x total diameter; For Low Voltage cables= 5 x total diameter)

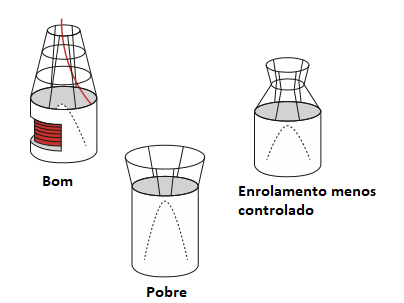

INSTALLATION - TYPES OF COILS (DRUMS)

1-) Mono Spiral Coil: it is the most common, it has a simple guide route that extends the life of the cable compared to other types. Also in these cable reels due to improved heat dissipation, the conductor size in power cables are generally smaller compared to other types of coils. The diameter and length of the cable is a main factor and must be considered for the application in mono-spiral coils: the good balance between the internal and external diameter of the spool will be critical to determine and control the tension of the cable.

2-) Random Twist Coil: The simplest type of spool existing. It operates without guides and the random layers can create severe operational difficulties such as coil slippage, abrupt pulling force, twists, abrasions and abnormal accumulations. For these reasons, this application can only support small cable diameters and short runs: 250 m maximum run and an approximate weight <4 kg/m.

3-) Multi Spiral Coil: Used when the cable has a large diameter and long lengths. The main advantage of using this type of reel is its ability to transport a large quantity of cable (even with large diameters) with constant winding tension and long distances. On the other hand, usually due to the location of the spool, it is also difficult to reduce the number of guides and changes of direction on this type of installation.

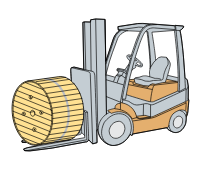

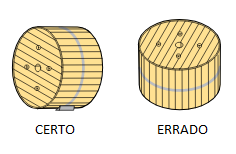

COILS - HANDLING AND STORAGE

It is recommended to store and handle cables on their respective coils in order to avoid defects caused by loose cables.

Avoid rolling the drums on their flanges, use a fork-lifter or crane to move the reel. If rolling cannot be avoided, do so against the winding direction in order to keep the cable firmly on the reel and prevent twisting or abrupt tensions.

– Move as close to the ground.

.- Move slowly and when in the correct location, do not make a sudden stop.

* Attention:

– Place the coil in the center of the fork.

– The width of the fork must be greater than the coil.

• Do not cover the coils.

• Do not roll more than 20 m.

• Do not use sharp objects when moving.

• Do not roll a damaged bobbin.

• Do not roll on an uneven surface.

• Do not store the coil near heaters or flammable places.

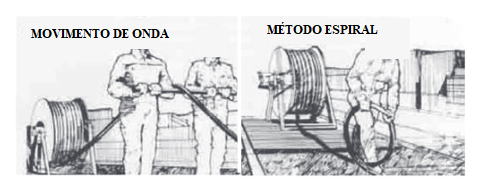

CABLE INSTALLATION

REMOVING THE TWIST:

INSTALLATION - VERTICAL APPLICATIONS - REELFLEX (K)NSHTÖU-J / (N)SHTÖU-J # REELFLEX PUR-HF # FESTFLEX (N) GRDGÖU

The best results are obtained with a stress relief coil. Open-end construction makes installation and relocation easier by providing better strain relief and outer jacket protection than squeezing the cable. Make at least 2 turns of cable around the drum. Table 1 (Radius of Curvature) shows the minimum bending radii for stress relief. If, on the other hand, anchoring is done by clamping over the sheath, a recommended length of sheath over the cable is approximately 25 times the total diameter of the cable. This will help spread the dynamic stresses over a sufficient surface area of the outer jacket to inhibit damage to the cable.

REELFLEX CABLE (K)NSHTÖU-J / (N)SHTÖU-J and REELFLEX PUR-HF

F ESTFLEX (N) GRDGÖU – APPLICATIONS IN BASKET

ELECTRICAL PARAMETERS

Voltage tests are used on flexible cables as required by DIN VDE 0250.

CALCULATION OF THE CABLE CROSS SECTION

CURRENT CAPACITY FOR CONTINUOUS OPERATION

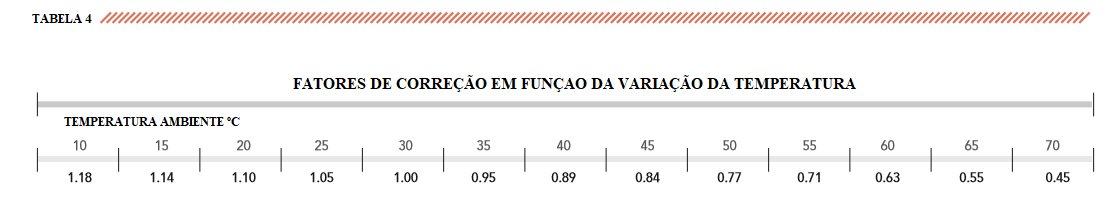

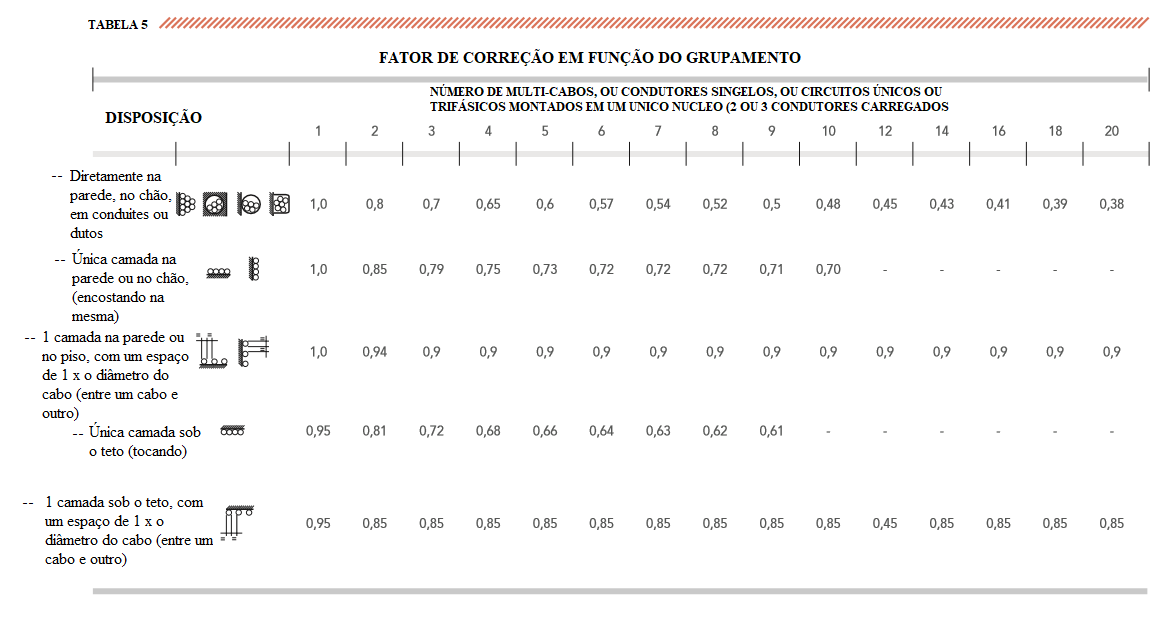

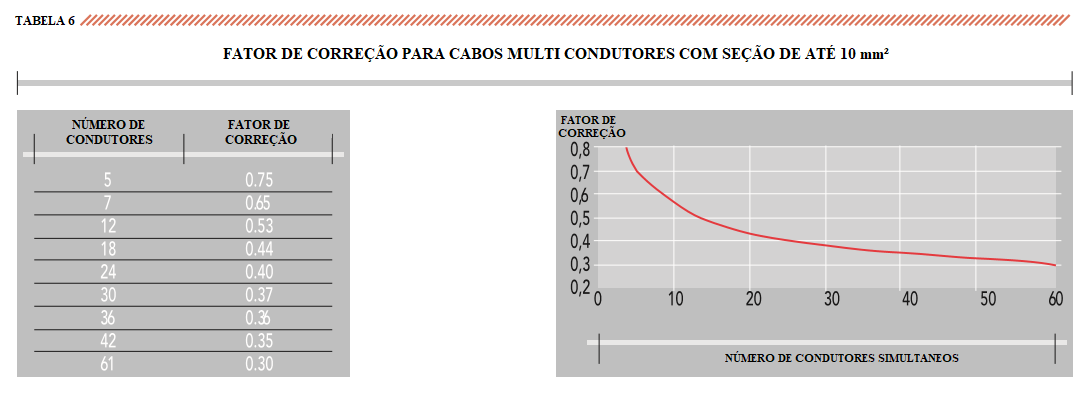

The calculation was made according to VDE as a precaution due to greater difficulties with heat dispersion for these types of cables. The values are for three-conductor cables, with or without a ground conductor, without movement with the cable on the ground and at an ambient temperature of 30 °C. For installations where it is known that cable life will be reduced as a result of high mechanical stress or wear on the outer jacket thermal aging will be of less importance. In this case, a maximum operating temperature of 90 °c and the capacities given in table 3 may be considered increased by approximately 7%.