Flexible Special Control Cables

Halogen Free Control Cables

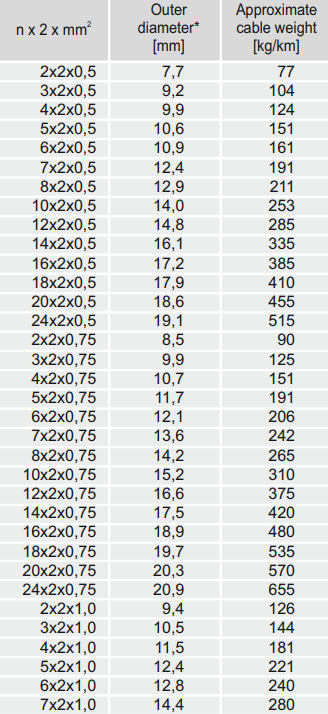

InnovCable Lihc11y

- Driver material: Naked copper wires

- Driver Class: According to DIN VDE 0295 Class 5 and IEC 60228 cl. 5

-Vein isolation: special halogen compound (LSZH), mixed polymers HA2 without halogen according to DIN VDE 0819-106

Nominal voltage: 300/500 V for gauges up to 0.75mm²

600/1000 V for gauges greater than 1 , 00mm² -HD 604 s1 (DIN VDE 0276-604) and according to IEC 60502-1

Ozone resistant according to IEC 60811-403 (DIN EN 60811-403)

Without Halogen as per 50267-2-1 (DIN EN 50267-2-1), IEC 60754-2

Flame retardant according to IEC 60332-1- 2 (DIN VDE 0482-332-1-2)

Smoke gas density as IEC 61034-2 (DIN VDE 0482-1034-2)

-White or black veins identified by sequential numerical recording, with Earth green vein option (g) according to EN 50334 (DIN EN 50334)

-Layered twisted.

- Armage in tinned copper mesh, approx coverage. 85%.

-Pur/Polyéter Outdoor Cover Ral 7001.

PUR/POLYER BASE, microbes resistant according to HD 22.10 S2 (DIN VDE 0207-363-2)

Ozone resistant according to IEC 60811-403 (DIN EN 60811 -403)

without halogen according to EN 50267-2-1 (DIN EN 50267-2-1), IEC 60754-1, IEC 60754-2

UV resistant according to ISO 4892-2 (DIN EN ISO 4892-2)

Oil resistant, grease, gasoline (in permanent contact requires verifying resistance)

Identification

External Identification Recording:

InnovCable LSZH JZ/Oz H N (x) or (g) mm² XXXXX V Of: XXXX/Year

according to HD 604 S1 Part 1 Section 3 (DIN VDE 0276-604)

Applicable Specifications

Applications

Cables are intended for signaling control circuits, control circuits in industrial applications, measurement technology, for transmission of analog and digital signals in industrial and automatic electronic control engineering systems for fixed installation and mobile/portable devices. A common tinned copper braid screen ensures very good protection against external electromagnetic fields (approximately 50 dB). Suitable for use in internal environments, in both dry and damp rooms. The LIHC11Y cable can also be installed outdoors - the special external coating compound (PUR) ensures UV resistance and greater mechanical protection. Cables classified according to EN 50575 (CPR)

Maximum Conductor Temperature

FIXED: min -50 ° C to +80 ° C

Mobile: min (not for use in cable drag currents) -40 ° C to +80 ° C

-Cold wind resistance according to HD 605 S2 (DIN VDE 0276-605)

-The cable can be installed at the place of use, observing the curvature rays in the temperature range of –40 ° C to +80 ° C.

Notes

G = with 1 green driver for earth;

In the construction of the cable can be used Polyester Petp tape

if it is necessary, without halogen according to EN 50267-2-1 (DIN 50267-2-1, IEC 60754-2

Compliance Declaration: Cable in compliance with the EC Directive 73/ 23/EEC for low voltage equipment

.

Cable and Individual core curvature radius:

- single curvature 7.5 x cable diameter

- 6.0 x cable diameter (acceptable)

- Multiple curvature 20 x cable diameter

-CA voltage test: 4 kV 50 Hz, 5 min according to HD 604 S1 (DIN VDE 0276-604)

-Min. 20 Mohm x Km According to HD 605 S2 (DIN VDE 0276-605)

-- Maximum Driver Resistance According to IEC 60228 and IEC 60228 (DIN VDE 0295)

- 8.5 kV dielectric stiffness

The tests were guaranteed were

carried out according to the following standards: DIN EN 50395 (VDE 0481-395)

IEC 60060-2 and IEC 60060-2 AMD 1 (DIN-EN 60060-2-)

Based on IEC 61442, IEC 60230 and VDE 0276 T620

The cables tolerate an outbreak of 1.2/50μs with a voltage with a voltage 5KV PICE

The outbreak test followed the standards:

IEC 60230: 1966

EN IEC 60230: 2002

VDE 0481-230: 2003

-Telerance of external cable diameter: +/- 8%

– We can produce, upon request, several other options and cable configurations. Innovcable reserves the right to change this catalog without prior notice.

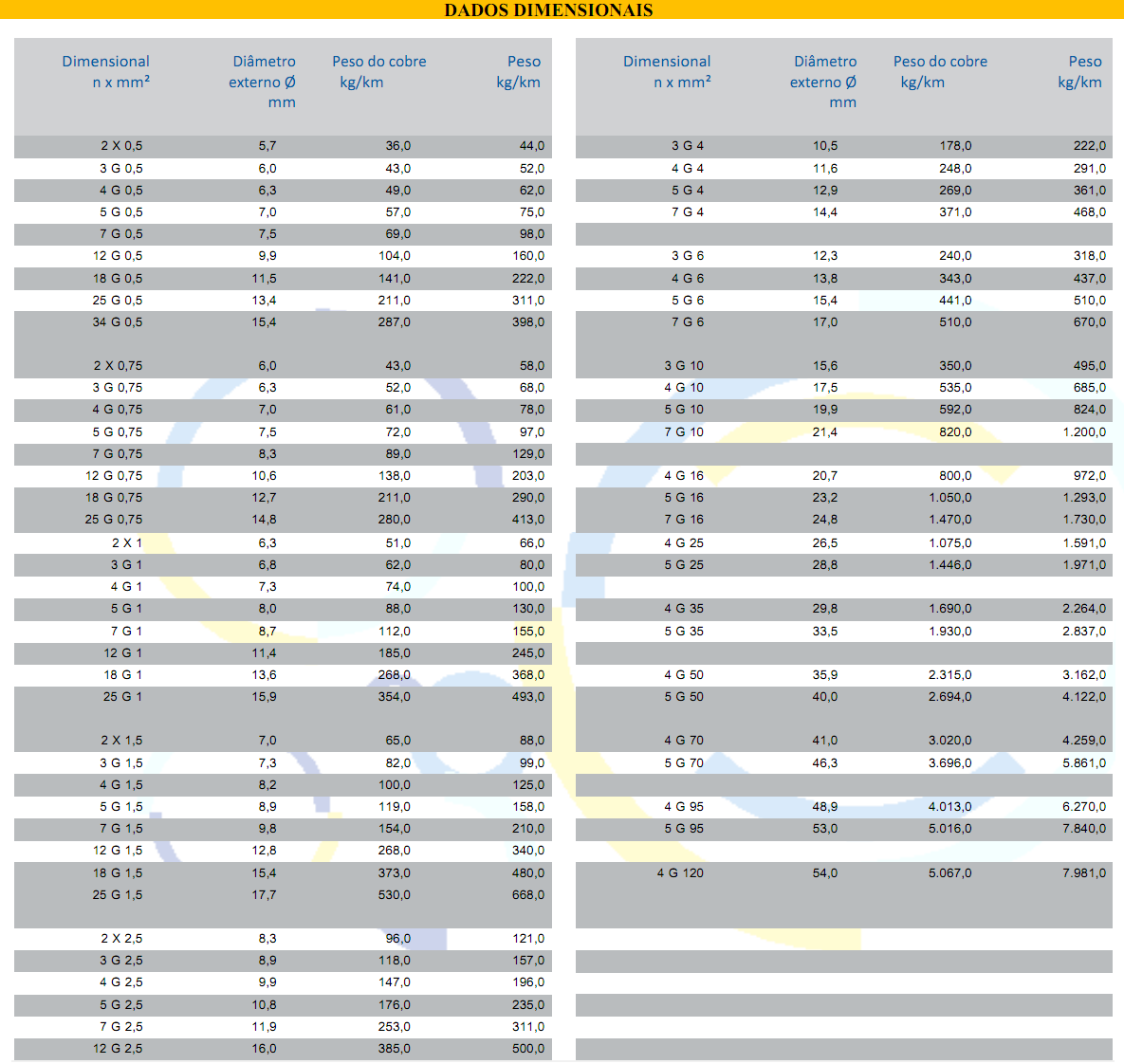

INNOVCABLE LSZH JZ/OZ – H

– Conductor material: bare copper wires

– Conductor class:according to DIN VDE 0295 class 5 and IEC 60228 cl. 5

– Vein Isolation: Special halogen-free compound (LSZH)

– White or black veins identified by sequential numerical engraving in black or yellow with earth green (G).

-Twisted in layers.

– External cover in special halogen-free compound (LSZH) manufactured in Gray RAL 7001.

– Manufactured free of harmful substances and silicone.

– Nominal voltage: 300/500V

– Test voltage: 3,000 V

– Conductor resistance: according to DIN VDE 0295 class 5e IEC 60228 cl. 5

– Insulation resistance: Minimum 20 MΩX Km.

– min. Fixed use bending radius:4 xd

– min. bending radius if movable: 15 xd

– Flame-retardant and halogen-free, non-corrosive in accordance with VDE 0482-332-1-1 (IEC 60332-3-24 Cat. C).

Identification

– All cables with identification (G) have 1 green conductor for earth, (x) without green conductor for earth.

External identification recording:

INNOVCABLE LSZH JZ/OZ H n (x) or (G) mm² 300/500V OF: XXXX/YEAR

Applicable Specifications

Applications

Cable for power, control and connections of electrical equipment in general, fixed and flexible applications without traction, can be applied in dry and humid locations. Halogen-free, low smoke emission, not emitting toxic smoke, suitable for areas where there is a concentration of people or valuables. Can be applied outdoors with UV application. Flame retardant and halogen-free, non-corrosive in accordance with VDE 0482-332-1-1 (IEC 60332-3-24 Cat. C). Manufactured free of harmful substances and silicone.

Maximum Conductor Temperature

Fixed: min-40° C / +90 ° C

Mobile: min-5° C / +90 ° C

– Temp. conductor + 90 ° C in operation; 250°C, in case of short circuit

Notes

G = with 1 green conductor for earth;

x = no green conductor for earth (OZ).

– We can produce, upon request, several other options and cable configurations. Innovcable reserves the right to change this catalog without prior notice.

INNOVCABLE LSZH JZ/OZ – CH

– Conductor material: bare copper wires

– Conductor class:according to DIN VDE 0295 class 5 and IEC 60228 cl. 5

– Vein Isolation: Special halogen-free compound (LSZH)

– White or black veins identified by sequential numerical engraving in black or yellow with earth green (G).

-Twisted in layers.

– Shielding in tinned copper mesh, coverage of approx. 85%.

– External cover in special halogen-free compound (LSZH) manufactured in Gray RAL 7001.

– Manufactured free of harmful substances and silicone.

– Nominal voltage: 300/500V

– Test voltage: 3,000 V

– Conductor resistance: according to DIN VDE 0295 class 5e IEC 60228 cl. 5

– Insulation resistance: Minimum 20 MΩX Km.

– min. Fixed use bending radius:4 xd

– min. bending radius if movable: 15 xd

– Flame-retardant and halogen-free, non-corrosive in accordance with VDE 0482-332-1-1 (IEC 60332-3-24 Cat. C).

Identification

– All cables with identification (G) have 1 green conductor for earth, (x) without green conductor for earth.

External identification engraving:

INNOVCABLE LSZH JZ/OZ-CH n (x) or (G) mm² 300/500V OF: XXXX/YEAR.

Applicable Specifications

Applications

Cable for power, control and connections of electrical equipment in general, fixed and flexible applications without traction, can be applied in dry and humid locations. Halogen-free, low smoke emission, not emitting toxic smoke, suitable for areas where there is a concentration of people or valuables. Can be applied outdoors with UV application. Flame retardant and halogen-free, non-corrosive in accordance with VDE 0482-332-1-1 (IEC 60332-3-24 Cat. C). Manufactured free of harmful substances and silicone.

Recommended for EMC applications. Shielding against electromagnetic interference.

Maximum Conductor Temperature

Fixed: min-40°C / +90°C

Mobile: min-5°C / +90°C

Notes

G = with 1 green conductor for earth;

x = no green conductor for earth (OZ).

– We can produce, upon request, several other options and cable configurations. Innovcable reserves the right to change this catalog without prior notice.

INNOVCABLE GIGAFLEX 500

– Conductor material: bare copper wires

– Conductor class: according to DIN VDE 0295 cl. 5, BS 6360 cl. 5 and IEC 60228 cl. 5

– Vein Insulation: Special elastomeric compound (P10) halogen-free (LSZH)

– White or black veins identified by sequential numerical engraving in black or yellow with earth green (G) in accordance with DIN VDE 0293.

-Twisted in layers.

– External cover in special elastomeric compound (P10) free of halogen (LSZH), manufactured in Gray RAL 7001.

– Manufactured free of harmful substances and silicone.

– Nominal voltage: 300/500V

– Test voltage: 3,000 V

– Conductor resistance: according to DIN VDE 0295 class 5e IEC 60228 cl. 5

– Insulation resistance: Minimum 20 MΩX Km.

– min. Fixed use bending radius:4 xd

– min. radius of curvature if movable: 10 xd

Bending test in accordance with DIN VDE 0281-2.

– Flame retardant and halogen-free, non-corrosive in accordance with VDE 0482-332-1-2 (IEC 60332-3-24 Cat. C), DIN EN/IEC 60332-1 (previous DIN VDE 0472 part 804 test method B)

LSZH= Low Smoke, Zero Halogen halogen)

– Recyclable product

Identification

– All cables with identification (G) have 1 green conductor for earth, (x) without green conductor for earth.

External identification recording:

INNOVCABLE GIGAFLEX 500 n (x) or (G) mm² 300/500V 125 OF: XXXX/YEAR

Applicable Specifications

Applications

Cable for power, control and connections of electrical equipment in general, fixed and flexible applications with low traction and high mechanical tension, can be applied in dry and humid locations. Halogen-free, low smoke emission, not emitting toxic smoke, suitable for areas where there is a concentration of people or valuables. Suitable for constructions of airports, cinemas, shopping malls, wind energy systems, naval constructions. Can be applied outdoors with UV protection and ozone resistance. Flame retardant and halogen-free, non-corrosive, resistant to oils and grease, resistant to abrasion and wear, Manufactured free of harmful substances and silicone.

Maximum Conductor Temperature

Fixed: min-40°C / +125°C

Mobile: min -40°C / +125°C

Notes

G = with 1 green conductor for earth;

x = no green conductor for earth.

– We can produce several other cable options and configurations upon request. Innovcable reserves the right to change this catalog without prior notice.

INNOVCABLE GIGAFLEX 500-C

– Conductor material: bare copper wires

– Conductor class: according to DIN VDE 0295 cl. 5, BS 6360 cl. 5 and IEC 60228 cl. 5

– Vein Insulation: Special elastomeric compound (P10) halogen-free (LSZH)

– White or black veins identified by sequential numerical engraving in black or yellow with earth green (G) in accordance with DIN VDE 0293.

-Twisted in layers.

– Polyester tape separator

– Tinned copper mesh shielding with approximately 85% coverage. (EMC protection)

– External cover in special elastomeric compound (P10) free of halogen (LSZH), manufactured in Gray RAL 7001.

– Manufactured free of harmful substances and silicone.

– Nominal voltage: 300/500V

– Test voltage: 3,000 V

– Conductor resistance: according to DIN VDE 0295 class 5e IEC 60228 cl. 5

– Insulation resistance: Minimum 20 MΩX Km.

– min. Fixed use bending radius:4 xd

– min. radius of curvature if movable: 10 xd

Bending test in accordance with DIN VDE 0281-2.

– Flame retardant and flame retardant and halogen-free, non-corrosive in accordance with VDE 0482-332-1-2 (IEC 60332-3-24 Cat. C), DIN EN/IEC 60332-1 (previous DIN VDE 0472 part 804 test method B)

– LSZH= Low Smoke, Zero Halogen halogen)

– EMC = Electro Magnetic Compatibility

– Recyclable product

Identification

– All cables with identification (G) have 1 green conductor for earth, (x) without green conductor for earth.

External identification recording:

INNOVCABLE GIGAFLEX 500-C n (x) or (G) mm² 300/500V 125°C OF: XXXX/YEAR

Applicable Specifications

Applications

Cable for power, control and connections of electrical equipment in general, EMC protection against electromagnetic interference, fixed and flexible applications with low traction and high mechanical tension, can be applied in dry and humid locations. Halogen-free, low smoke emission, not emitting toxic smoke, suitable for areas where there is a concentration of people or valuables. Suitable for constructions of airports, cinemas, shopping malls, wind energy systems, naval constructions. Can be applied outdoors with UV protection and ozone resistance. Flame retardant and halogen-free, non-corrosive, resistant to oils and grease, resistant to abrasion and wear, Manufactured free of harmful substances and silicone.

Maximum Conductor Temperature

Fixed: min-40°C / +125°C

Mobile: min -40°C / +125°C

Notes

G = with 1 green conductor for earth;

x = no green conductor for earth.

– We can produce several other cable options and configurations upon request. Innovcable reserves the right to change this catalog without prior notice.