Naval Cables – NEK-606/IEC – SHF2 Resistance

Instrumentation and communication cables – Flame resistant – SHF2 resistance

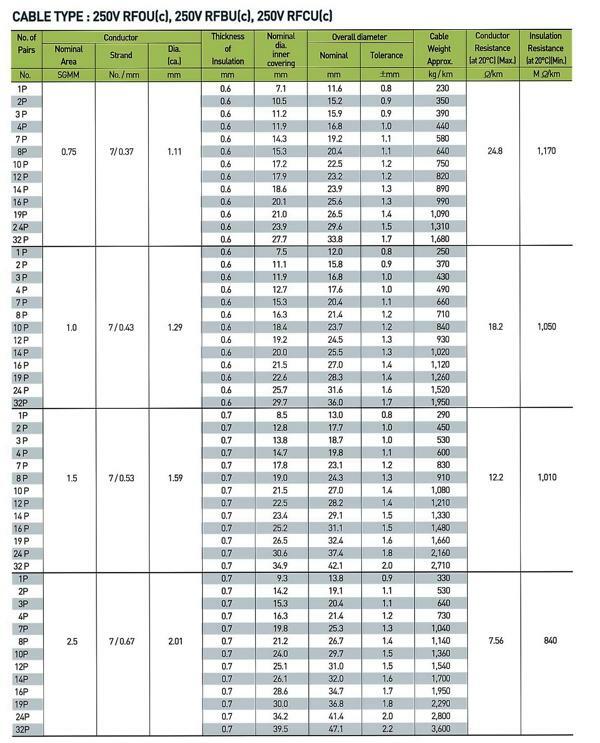

INNOVCABLE Instrumentation and Communication 150/250(300)V RFOU(c), RFBU(c), RFCU(c), TFOU(c), TFBU(c), TFCU(c) – S2 and S2/S6 – SHF2 Resistance

1) Conductor formed by tinned electrolytic copper wires, soft temper, class 5 stranding, in accordance with IEC 60228. *1

2) Insulation of conductors in special halogen-free compound LSOH – (Code R(HEPR/EPR), T (XLPE)) – according to IEC 60092-351.

3) Twisted conductors forming Pairs, Triples or Quads.

4) Pairs or Trios gathered together and identified by sequential numbers, non-hygroscopic flame retardant filaments can be used in the construction of the conductor and tapes can be applied to the conductors.

5-) Collective shielding in aluminized polyester tape + drain wire (Code (c))

6) Internal cover in halogen-free polyolefin compound LSOH – (Code F)

7) Frame: *2

– Mesh of tinned copper wires (Code 0)

– Bronze wire mesh (Code B)

– Galvanized steel wire mesh (Code C)

8) Final cover in halogen-free polyolefin compound LSOH (SHF2). (Code U)

9) External cover in gray (Not Intrinsically Safe) or Blue (Intrinsically Safe – IS)

Identification

Conductors in colors:

Pair: Black – Light Blue

Trio: Black – Light Blue – Brown

Quadra: Black – Light Blue – Brown – Gray

Identification on the External Cover (example): “Year” Innovcable 01 RFOU(C) 250V S2/S6 4PAIR 0.75mm2 IEC 60092-376 IEC 60332-3-22 ARCTIC GRADE Cold bend (-40 deg. C) / Cold impact (- 35deg.C)

Applicable Specifications

Applications

Instrumentation, communication, control and alarm cable, for fixed installations in Ex – and safe areas. Meets NEK TS 606:2009 resistance requirement. Meets cold/cold curve impact requirement in CSA 22.2 0.3-01 and IEC 60092-350 Clause 8.9 and Annex E at -40°C/-35°C.

Maximum Conductor Temperature

90°C

Notes

1) The tinned copper conductor can be manufactured in class 2.

2) Separator tape can be applied before/after the frame.

3) Operating voltage: 150/250(300)V

**Innovcable reserves the right to change this catalog without prior notice.**

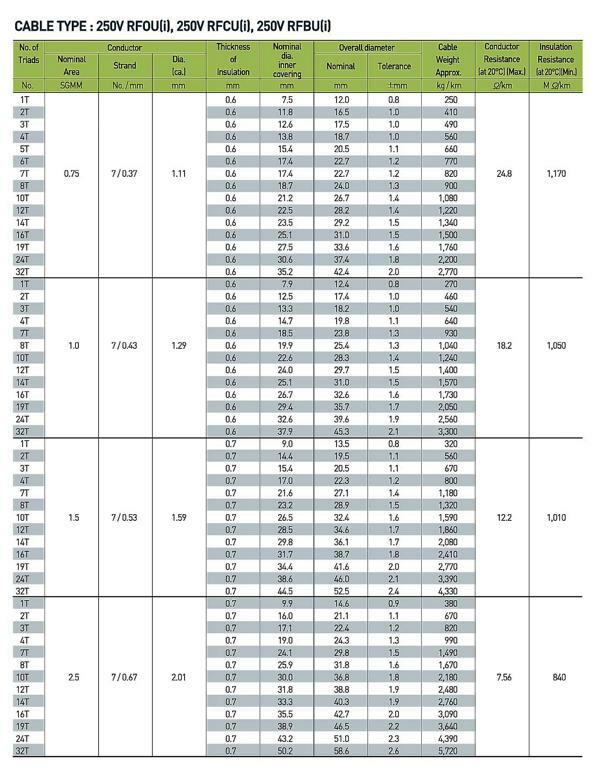

INNOVCABLE Instrumentation and Communication 150/250(300)V RFOU(i), RFBU(i), RFCU(i), TFOU(i), TFBU(i), TFCU(i) – S1 and S1/S5 – SHF2 Resistance

1) Conductor formed by tinned electrolytic copper wires, soft temper, class 5 stranding, in accordance with IEC 60228. *1

2) Insulation of conductors in special halogen-free compound LSOH – (Code R(HEPR/EPR), T (XLPE)) – according to IEC 60092-351.

3) Twisted conductors forming Pairs, Triples or Quads.

4) Individual shielding in aluminized polyester tape + drain wire (Code (i))

5) Pairs or trios put together and identified by sequential numbers, non-hygroscopic flame retardant filaments can be used in the construction of the conductor and tapes can be applied on drivers.

6) Inner cover in halogen-free polyolefin compound LSOH – (Code F)

7) Frame: *2

– Mesh of tinned copper wires (Code 0)

– Mesh of bronze wires (Code B)

– Mesh of galvanized steel wires (Code C)

8) Final covering in halogen-free polyolefin compound LSOH (SHF2). (Code U)

9) External cover in gray (Not Intrinsically Safe) or Blue (Intrinsically Safe – IS)

Identification

Conductors in colors:

Pair: Black – Light Blue

Trio: Black – Light Blue – Brown

Quadra: Black – Light Blue – Brown – Gray

Identification on the External Cover (example): “Year” Innovcable 01 RFOU(i) 250V S2/S6 4PAIR 0.75mm2 IEC 60092-376 IEC 60332-3-22 ARCTIC GRADE Cold bend (-40 deg. C) / Cold impact (- 35deg.C)

Applicable Specifications

Applications

Instrumentation, communication, control and alarm cable, for fixed installations in Ex – and safe areas. Meets resistance requirement in NEK TS 606:2009. Meets cold/cold curve impact requirement in CSA 22.2 0.3-01 and IEC 60092-350 Clause 8.9 and Annex E at -40°C/-35°C.

Maximum Conductor Temperature

90°C

Notes

1) The tinned copper conductor can be manufactured in class 2.

2) Separator tape can be applied before/after the frame.

3) Operating voltage: 150/250(300)V

**Innovcable reserves the right to change this catalog without prior notice.**

INNOVCABLE Instrumentation and Communication 150/250(300)V RFOU(i&c), RFBU(i&c), RFCU(i&c), TFOU(i&c), TFBU(i&c), TFCU(i&c) – SHF2 Resistance

1) Conductor formed by tinned electrolytic copper wires, soft temper, class 5 stranding, in accordance with IEC 60228. *1

2) Insulation of conductors in special halogen-free compound LSOH – (Code R(HEPR/EPR), T (XLPE)) – according to IEC 60092-351.

3) Twisted conductors forming Pairs, Triples or Quads.

4) Individual shielding in aluminized polyester tape + drain wire (Code (i))

5) Pairs or trios put together and identified by sequential numbers, non-hygroscopic flame retardant filaments can be used in the construction of the conductor and tapes can be applied on drivers.

6) Collective shielding in aluminized polyester tape + drain wire (Code (c))

7) Internal cover in halogen-free polyolefin compound LSOH – (Code F)

8) Frame: *2

– Tinned copper wire mesh (Code 0 )

– Bronze wire mesh (Code B)

– Galvanized steel wire mesh (Code C)

9) Cover final in halogen-free polyolefin compound LSOH (SHF2). (Code U)

10) External cover in gray (Not Intrinsically Safe) or Blue (Intrinsically Safe – IS)

Identification

Conductors in colors:

Pair: Black – Light Blue

Trio: Black – Light Blue – Brown

Quadra: Black – Light Blue – Brown – Gray

Identification on the External Cover (example): “Year” Innovcable 01 RFOU(i&c) 250V 4PAIR 0.75mm2 IEC 60092-376 IEC 60332-3-22 ARCTIC GRADE Cold bend (-40 deg. C) / Cold impact (-35deg. C )

Applicable Specifications

Applications

Instrumentation, communication, control and alarm cable, for fixed installations in Ex – and safe areas. Individual and collective shielding. Meets NEK TS 606:2009 resistance requirement. Meets cold/cold curve impact requirement in CSA 22.2 0.3-01 and IEC 60092-350 Clause 8.9 and Annex E at -40°C/-35°C.

Maximum Conductor Temperature

90°C

Notes

1) The tinned copper conductor can be manufactured in class 2.

2) Separator tape can be applied before/after the frame.

3) Operating voltage: 150/250(300)V

**Innovcable reserves the right to change this catalog without prior notice.**

INNOVCABLE Instrumentation and Communication 150/250(300)V RU(i), TU(i), – S11 – SHF2 Resistance

1) Conductor formed by tinned electrolytic copper wires, soft temper, class 5 stranding, in accordance with IEC 60228. *1

2) Insulation of conductors in special halogen-free compound LSOH – (Code R(HEPR/EPR), T (XLPE)) – according to IEC 60092-351.

3) Twisted conductors forming Pairs, Triples or Quads.

4) Individual shielding in aluminized polyester tape + drain wire (Code (i))

5) Pairs or trios put together and identified by sequential numbers, non-hygroscopic flame retardant filaments can be used in the construction of the conductor and tapes can be applied on drivers.

6) Final cover in halogen-free polyolefin compound LSOH (SHF2). (Code U)

7) External cover in gray (Not Intrinsically Safe) or Blue (Intrinsically Safe – IS)

Identification

Conductors in colors:

Pair: Black – Light Blue

Trio: Black – Light Blue – Brown

Quadra: Black – Light Blue – Brown – Gray

Identification on the External Cover (example): “Year” Innovcable 01 RU(i) 250V S11 2 pair 0.75 mm2 IEC 60092-376 IEC60332-3-22

Applicable Specifications

Applications

Instrumentation, communication, control and alarm cable, for fixed installations in Ex areas (Zone 2) and safe areas. Meets NEK TS 606:2009 strength requirement.

Maximum Conductor Temperature

90°C

Notes

1) Tinned copper Conductor can be manufactured in class 2.

2) Operating voltage: 150/250(300)V

**Innovcable reserves the right to change this catalog without prior notice.**

INNOVCABLE Instrumentation and Communication 150/250(300)V RU(c), TU(c), – S12 – SHF2 Resistance

1) Conductor formed by tinned electrolytic copper wires, soft temper, class 5 stranding, in accordance with IEC 60228. *1

2) Insulation of conductors in special halogen-free compound LSOH – (Code R(HEPR/EPR), T (XLPE)) – according to IEC 60092-351.

3) Twisted conductors forming Pairs, Triples or Quads.

4) Pairs or Trios gathered together and identified by sequential numbers, non-hygroscopic flame retardant filaments can be used in the construction of the conductor and tapes can be applied to the conductors.

5-) Collective shielding in aluminized polyester tape + drain wire (Code (c))

6) Final covering in halogen-free polyolefin compound LSOH (SHF2). (Code U)

7) External cover in gray (Not Intrinsically Safe) or Blue (Intrinsically Safe – IS)

Identification

Conductors in colors:

Pair: Black – Light Blue

Trio: Black – Light Blue – Brown

Quadra: Black – Light Blue – Brown – Gray

Identification on the External Cover (example): “Year” Innovcable 01 RU(c) 250V S12 2 pair 0.75 mm2 IEC 60092-376 IEC60332-3-22

Applicable Specifications

Applications

Instrumentation, communication, control and alarm cable, for fixed installations in Ex areas (Zone 2) and safe areas. Meets NEK TS 606:2009 strength requirement.

Maximum Conductor Temperature

90°C

Notes

1) Tinned copper Conductor can be manufactured in class 2.

2) Operating voltage: 150/250(300)V

**Innovcable reserves the right to change this catalog without prior notice.**

INNOVCABLE Instrumentation and Communication 150/250(300)V RU(i&c), TU(i&c), – SHF2 Resistance

1) Conductor formed by tinned electrolytic copper wires, soft temper, class 5 stranding, in accordance with IEC 60228. *1

2) Insulation of conductors in special halogen-free compound LSOH – (Code R(HEPR/EPR), T (XLPE)) – according to IEC 60092-351.

3) Twisted conductors forming Pairs, Triples or Quads.

4) Individual shielding in aluminized polyester tape + drain wire (Code (i))

5) Pairs or trios put together and identified by sequential numbers, non-hygroscopic flame retardant filaments can be used in the construction of the conductor and tapes can be applied on drivers.

6) Collective shielding in aluminized polyester tape + drain wire (Code (c))

7) Final covering in halogen-free polyolefin compound LSOH (SHF2). (Code U)

8) External cover in gray (Not Intrinsically Safe) or Blue (Intrinsically Safe – IS)

Identification

Conductors in colors:

Pair: Black – Light Blue

Trio: Black – Light Blue – Brown

Quadra: Black – Light Blue – Brown – Gray

Identification on the External Cover (example): “Year” Innovcable 01 RU(i&c) 250V 4PAIR 0.75mm2 IEC 60092-376 IEC 60332-3-22

Applicable Specifications

Applications

Instrumentation, communication, control and alarm cable, for fixed installations in Ex areas (Zone 2) and safe areas. Individual and collective shielding. Meets NEK TS 606:2009 strength requirement.

Maximum Conductor Temperature

90°C

Notes

1) Tinned copper Conductor can be manufactured in class 2.

2) Operating voltage: 150/250(300)V

**Innovcable reserves the right to change this catalog without prior notice.**