Naval Cables – IEC Standard

Fire resistant marine cables IEC 60331

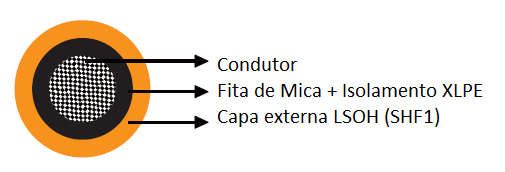

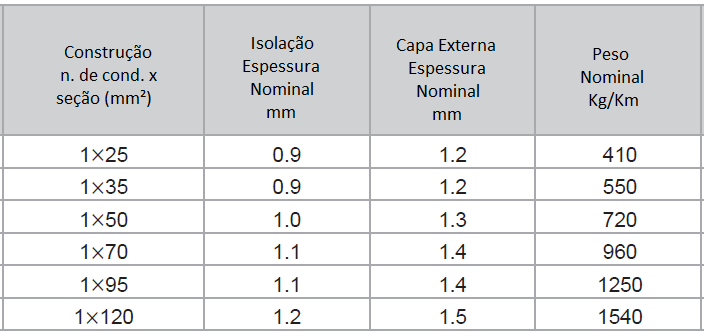

INNOVCABLE CONTROL/POWER – FIRE RESISTANT – MICA TAPE/XLPE/SHF1 – 1 conductor – 0.6/1Kv – IEC 60331

1) Conductor formed by bare or tinned electrolytic copper wires, soft temper, class 5 stranding, in accordance with IEC 60228. *1.7

2) Insulation of conductors in mica tape and special halogen-free compound LSOH (XLPE) .*4

3) Final cover in halogen-free polyolefin compound LSOH (SHF1), gray in color.*2.5

Identification

External Recording:

INNOVCABLE INNOVSHORE FIRE RESISTANT XLPE/SHF1 __mm² 0.6/1KV 90°C OF: XXXX/YEAR IEC 60092/60331

Applicable Specifications

Applications

Naval Cables Fire Resistant for 0.6 / 1 kV control and control with special properties for non -armed electrical installations for use on board ships and offshore units at all fixed installation locations. 90 ° C temperature class, flame retardant (IEC 60332-3), low smoke emission, halogen free, low toxicity and “fire barrier” resistant (IEC 60331, 950 ° C).

Maximum Conductor Temperature

CONTINUOUS SERVICE: 90°C – IEC 60092-360

SHORT CIRCUIT: 250°C

Notes

* We manufacture with other configurations:

1) The tinned copper conductor can be manufactured in class 2.

2) External cover colors: Nomenclature to be added to the end of the code: VM – Red // VD – Green // BR – White / / PT – Black // AZ – Blue // LJ – Orange

We can manufacture other colors upon request.

3-) Other dimensions: from 1.5mm² to 500mm² (Also in AWG)

4) Vein insulation material:

EPR – 90 ºC

HEPR – 90 ºC

HF90 – 90 ºC

5) Intermediate cover and cover material:

ST2

SE

SHF2

6) At Innovcable's discretion, separators and/or fillings made of compatible material may be used.

7) Nomenclature to be added to the end of the code depending on the type of conductor:

Bare copper conductor – CN

Tinned copper conductor – SN

Naval Cables Fire Resistant

**Innovcable reserves the right to change this catalog without prior notice.**

INNOVCABLE CONTROL/POWER – FIRE RESISTANT – MICA TAPE/XLPE/SHF1 – Multiconductor – 0.6/1Kv – IEC 60331

1) Conductor formed by bare or tinned electrolytic copper wires, soft temper, class 5 stranding, in accordance with IEC 60228. *1.7

2) Insulation of conductors in mica tape and special halogen-free compound LSOH (XLPE) .*4

3) Final cover in halogen-free polyolefin compound LSOH (SHF1), gray in color.*2.5

Identification

External Recording:

INNOVCABLE INNOVSHORE FIRE RESISTANT XLPE/SHF1 __mm² 0.6/1KV 90°C OF: XXXX/YEAR IEC 60092/60331.

Conductor insulation colors:

2 conductors: black and white or sequentially numbered white or black veins.

3 conductors: black, white and red or sequentially numbered white or black veins.

4 conductors: black, white red and blue or sequentially numbered white or black veins.

5 conductors: black, red white, blue and gray or sequentially numbered white or black veins.

Multiconductors: > 5 conductors – white or black veins numbered sequentially.

Applicable Specifications

Applications

Naval Cables Fire Resistant for 0.6 / 1 kV control and control with special properties for non -armed electrical installations for use on board ships and offshore units at all fixed installation locations. 90 ° C temperature class, flame retardant (IEC 60332-3), low smoke emission, halogen free, low toxicity and “fire barrier” resistant (IEC 60331, 950 ° C).

Maximum Conductor Temperature

CONTINUOUS SERVICE: 90°C – IEC 60092-360

SHORT CIRCUIT: 250°C

Notes

* We manufacture with other configurations:

1) The tinned copper conductor can be manufactured in class 2.

2) External cover colors: Nomenclature to be added to the end of the code: VM – Red // VD – Green // BR – White / / PT – Black // AZ – Blue // LJ – Orange

We can manufacture other colors upon request.

3-) Other dimensions: from 1.5mm² to 70.0mm² (Also in AWG)

Other formations up to 71 conductors (see maximum per gauge).

4) Vein insulation material:

EPR – 90 ºC

HEPR – 90 ºC

HF90 – 90 ºC

5) Intermediate cover and cover material:

ST2

SE

SHF2

6) At Innovcable's discretion, separators and/or material fillers may be used compatible.

7) Nomenclature to be added to the end of the code depending on the type of conductor:

Bare copper conductor – CN

Tinned copper conductor – SN

Naval Cables Fire Resistant

**Innovcable reserves the right to change this catalog without prior notice.**

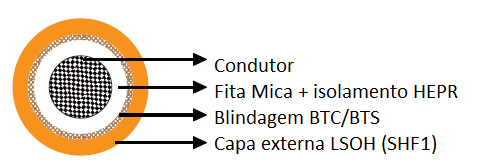

INNOVCABLE SHIELDED CONTROL/POWER BTC/BTS – FIRE RESISTANT – MICA TAPE/HEPR/SHF1 – 1 conductor – 0.6/1Kv – IEC 60331

1) Conductor formed by bare or tinned electrolytic copper wires, soft temper, class 5 stranding, in accordance with IEC 60228. *1.7

2) Insulation of conductors in mica tape and special halogen-free compound LSOH (HEPR) .*4

3) Shielding: Braid of bare copper (BTC), tinned copper (BTS) wires with >90% coverage. *8

4) Final cover in halogen-free polyolefin compound LSOH (SHF1), gray in color.*2.5

Identification

External Recording:

INNOVCABLE INNOVSHORE FIRE RESISTANT BTC/BTS HEPR/SHF1__mm² 0.6/1KV 90°C OF: XXXX/YEAR IEC 60092/60331

Applicable Specifications

Applications

Naval Cables Fire Resistant Armored for 0.6 / 1 kV control with special properties for electrical installations for use on board ships and offshore units at all fixed installation locations. The shield proves protection against electromagnetic interference, according to the standard. Temperature class of 90 ° C, flame retardator (IEC 60332-3), low smoke emission, halogen free, low toxicity and fire resistant “fire barrier” (IEC 60331, 950 ° C)

Maximum Conductor Temperature

CONTINUOUS SERVICE: 90°C – IEC 60092-360

SHORT CIRCUIT: 250°C

Notes

* We manufacture with other configurations:

1) The tinned copper conductor can be manufactured in class 2.

2) External cover colors: Nomenclature to be added to the end of the code: VM – Red // VD – Green // BR – White / / PT – Black // AZ – Blue // LJ – Orange

We can manufacture other colors upon request.

3-) Other dimensions: from 1.5mm² to 500mm² (Also in AWG)

)

Vein insulation material:

EPR

– 90 ºC

HF90-

90

ºC 6) At Innovcable's discretion, separators and/or fillings made of compatible material may be used.

7) Nomenclature to be added to the end of the code depending on the type of conductor:

Bare copper conductor – CN

Tinned copper conductor – SN

8) Types of Shields:

BTS – Tinned copper wire braid frame

BTC – Braid frame of bare copper wires

Naval Cables Fire Resistant

**Innovcable reserves the right to change this catalog without prior notice.**

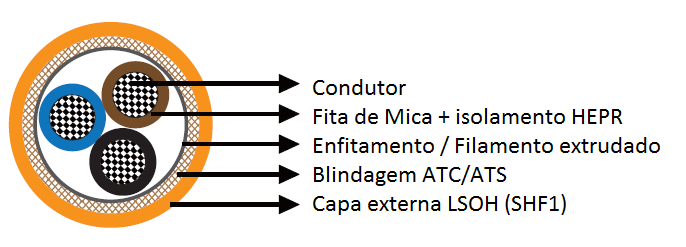

INNOVCABLE SHIELDED CONTROL/POWER BTC/BTS – FIRE RESISTANT – MICA TAPE/HEPR/SHF1 – Multiconductor – 0.6/1Kv – IEC 60331

1) Conductor formed by bare or tinned electrolytic copper wires, soft temper, class 5 stranding, in accordance with IEC 60228. *1.7

2) Insulation of conductors in mica tape and special halogen-free compound LSOH (HEPR) .*4

3) Helically applied polyester tape or extruded tape.

4) Shielding: Braid of bare copper (BTC), tinned copper (BTS) wires with >90% coverage. *8

5) Final cover in halogen-free polyolefin compound LSOH (SHF1), gray in color.*2.5

Identification

External Recording:

INNOVCABLE INNOVSHORE FIRE RESISTANT BTC/BTS HEPR/SHF1 __X__mm² 0.6/1KV 90°C OF: XXXX/YEAR IEC 60092/60331

Conductor insulation colors: *3

2 conductors: black and white or sequentially numbered white or black veins.

3 conductors: black, white and red or sequentially numbered white or black veins.

4 conductors: black, white red and blue or sequentially numbered white or black veins.

5 conductors: black, red white, blue and gray or sequentially numbered white or black veins.

Multiconductors: > 5 conductors – white or black veins numbered sequentially.

Applicable Specifications

Applications

Naval Cables Fire Resistant Armored for 0.6 / 1 kV control with special properties for electrical installations for use on board ships and offshore units at all fixed installation locations. The shield proves protection against electromagnetic interference, according to the standard. 90 ° C temperature class, flame retardant (IEC 60332-3), low smoke emission, halogen free, low toxicity and “fire barrier” resistant (IEC 60331, 950 ° C).

Maximum Conductor Temperature

CONTINUOUS SERVICE: 90°C – IEC 60092-360

SHORT CIRCUIT: 250°C

Notes

* We manufacture with other configurations:

1) The tinned copper conductor can be manufactured in class 2.

2) External cover colors: Nomenclature to be added to the end of the code: VM – Red // VD – Green // BR – White / / PT – Black // AZ – Blue // LJ – Orange

We can manufacture other colors upon request.

3-) Other dimensions: from 1.5mm² to 70.0mm² (Also in AWG)

Other formations up to 71 conductors (see maximum per gauge).

)

Vein insulation material:

EPR –

90

ºC

HF90 –

90 ºC compatible. 7) Nomenclature to be added to the end of the code depending on the type of conductor:

Bare copper conductor – CN

Tinned copper conductor – SN

8) Types of Shields:

BTS – Tinned copper wire braid frame

BTC – Braid frame of bare copper wires

Naval Cables Fire Resistant

**Innovcable reserves the right to change this catalog without prior notice.**

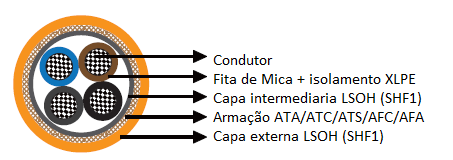

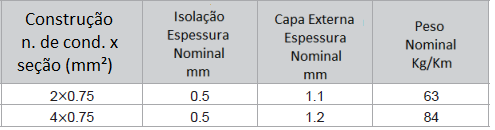

INNOVCABLE CONTROL/ARMED POWER ATA/ATC/ATS/AFC/AFA – FIRE RESISTANT – MICA TAPE/XLPE/SHF1 – 1 conductor – 0.6/1Kv – IEC 60331

1) Conductor formed by bare or tinned electrolytic copper wires, soft temper, class 5 stranding, in accordance with IEC 60228. *

2) Insulation of conductors in mica tape and special halogen-free compound LSOH (XLPE).*

3 ) Frame: Braid of galvanized steel wires (ATA), bare copper (ATC), tinned copper (ATS) with >90% coverage, tape copper (AFC) or steel tape (AFA), applied with overlap. *

4) Final cover in halogen-free polyolefin compound LSOH (SHF1), gray in color.*

Identification

External recording:

INNOVCABLE INNOVSHORE FIRE RESISTANT ATA/ATC/ATS/AFC/AFA XLPE/SHF1 __mm² 0.6/1KV 90°C OF: XXXX/YEAR IEC 60092/60331

Applicable Specifications

Applications

Naval Cables Fire Resistant armed for 0.6 / 1 kV control and control with special properties for electrical installations for use on board ships and offshore units at all fixed installation locations. The frame proves protection where necessary, as standard. 90 ° C temperature class, flame retardant (IEC 60332-3), low smoke emission, halogen free, low toxicity and “fire barrier” resistant (IEC 60331, 950 ° C).

Maximum Conductor Temperature

CONTINUOUS SERVICE: 90°C – IEC 60092-360

SHORT CIRCUIT: 250°C

Notes

* We manufacture with other configurations:

1) The tinned copper conductor can be manufactured in class 2.

2) External cover colors: Nomenclature to be added to the end of the code: VM – Red // VD – Green // BR – White / / PT – Black // AZ – Blue // LJ – Orange

We can manufacture other colors upon request.

3-) Other dimensions: from 1.5mm² to 500mm² (Also in AWG)

4) Vein insulation material:

EPR – 90 ºC

HEPR – 90 ºC

HF90 – 90 ºC

5) Intermediate cover and cover material:

ST2

SE

SHF2

6) At Innovcable's discretion, separators and/or fillings made of compatible material may be used.

7) Nomenclature to be added to the end of the code depending on the type of conductor:

Bare copper conductor – CN

Tinned copper conductor – SN

9) Types of frames:

ATA – Galvanized steel wire braid frame

ATS – Braid frame of tinned copper wires

ATC – Frame in braid of bare copper wires

AFC – Frame in copper tape

AFA – Frame in galvanized steel tape

Naval Cables Fire Resistant

**Innovcable reserves the right to change this catalog without prior notice.**

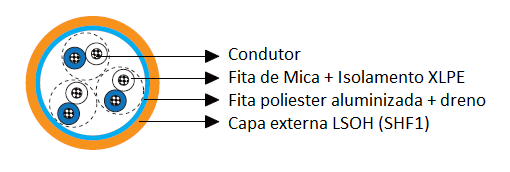

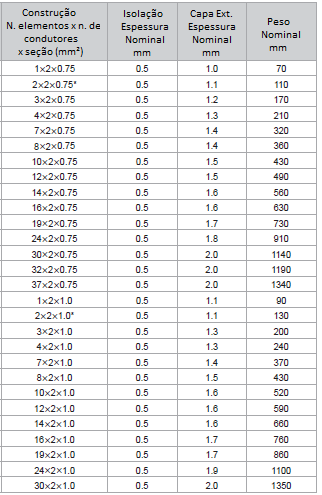

INNOVCABLE CONTROL / ARMED POWER ATA/ATC/ATS/AFC/AFA – FIRE RESISTANT – MICA TAPE/XLPE/SHF1 – Multiconductor – 0.6/1Kv – IEC 60331

1) Conductor formed by bare or tinned electrolytic copper wires, soft temper, class 5 stranding, in accordance with IEC 60228. *1.7

2) Insulation of conductors in mica tape and special halogen-free compound LSOH (XLPE) .*4

3) Inner cover in halogen-free polyolefin compound LSOH (SHF1). *5

4) Frame: Braid of galvanized steel wires (ATA), bare copper (ATC), tinned copper (ATS) with coverage >90%, copper tape (AFC) or steel tape (AFA), applied with overlap . *8

5) Final cover in halogen-free polyolefin compound LSOH (SHF1), gray in color.*2.5

Identification

External Recording:

INNOVCABLE INNOVSHORE FIRE RESISTANT ATA/ATC/ATS/AFC/AFA

Conductor insulation colors: *3

2 conductors: black and white or sequentially numbered white or black veins.

3 conductors: black, white and red or sequentially numbered white or black veins.

4 conductors: black, white red and blue or sequentially numbered white or black veins.

5 conductors: black, red white, blue and gray or sequentially numbered white or black veins.

Multiconductors: > 5 conductors – white or black veins numbered sequentially.

Applicable Specifications

Applications

Naval Cables Fire Resistant armed for 0.6 / 1 kV control and control with special properties for electrical installations for use on board ships and offshore units at all fixed installation locations. The frame proves protection where necessary, as standard. 90 ° C temperature class, flame retardant (IEC 60332-3), low smoke emission, halogen free, low toxicity and “fire barrier” resistant (IEC 60331, 950 ° C).

Maximum Conductor Temperature

CONTINUOUS SERVICE: 90°C – IEC 60092-360

SHORT CIRCUIT: 250°C

Notes

* We manufacture with other configurations:

1) The tinned copper conductor can be manufactured in class 2.

2) External cover colors: Nomenclature to be added to the end of the code: VM – Red // VD – Green // BR – White / / PT – Black // AZ – Blue // LJ – Orange

We can manufacture other colors upon request.

3-) Other dimensions: from 1.5mm² to 70.0mm² (Also in AWG)

Other formations up to 71 conductors (see maximum per gauge).

4) Vein insulation material:

EPR – 90 ºC

HEPR – 90 ºC

HF90 – 90 ºC

5) Intermediate cover and cover material:

ST2

SE

SHF2

6) At Innovcable's discretion, separators and/or material fillers may be used compatible.

7) Nomenclature to be added to the end of the code depending on the type of conductor:

Bare copper conductor – CN

Tinned copper conductor – SN

8) Types of frames:

ATA – Galvanized steel wire braid frame

ATS – Braid frame of tinned copper wires

ATC – Frame in braid of bare copper wires

AFC – Frame in copper tape

AFA – Frame in galvanized steel tape

Naval Cables Fire Resistant

**Innovcable reserves the right to change this catalog without prior notice.**

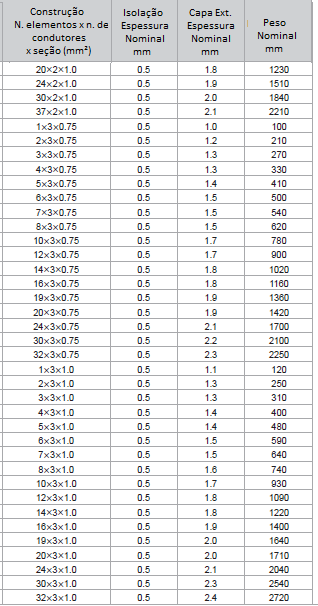

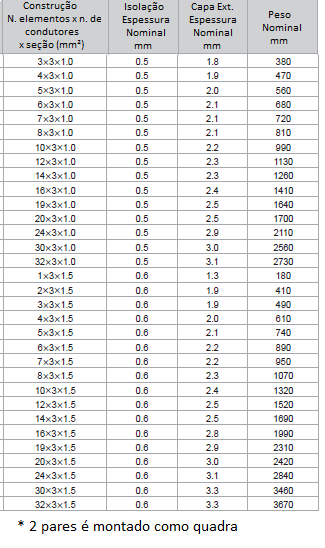

INNOVCABLE INSTRUMENTATION / CONTROL – FIRE RESISTANT – MICA TAPE/XLPE/SHF1 – Multiconductor – 0.15/0.25Kv (300V) – IEC 60331

1) Conductor formed by bare or tinned electrolytic copper wires, soft temper, class 5 stranding, in accordance with IEC 60228. *1.7

2) Insulation of conductors in mica tape and special halogen-free compound LSOH (XLPE) .*4

3) Final cover in halogen-free polyolefin compound LSOH (SHF1), gray in color.*2.5

Identification

INNOVCABLE INNOVSHORE FIRE RESISTANT INSTRUMENTATION XLPE/SHF1 __mm² 0.15/0.25KV 90°C OF: XXXX/YEAR IEC 60092/60331.

– Black or white veins numbered sequentially. *3

Applicable Specifications

Applications

Naval Cables Fire Resistant, 90 ° C temperature class, flame retarder (IEC 60332-3), low smoke emission, halogen free, low toxicity and “fire barrier” (IEC 60331, 950 ° C).

Built and designed for the demanding offshore drilling environment and the naval industry.

Used on board ships in fixed facilities, trays, gutters, conduits, panels, among others. Suitable for use in control, command and signaling circuits in accordance with IEC 60092-352. Innovshore control/instrumentation cables 0.15/0.25kV offers maximum resistance to chemicals, humidity and UV rays. Exceed the specifications of the indicated IEC's.

Maximum Conductor Temperature

CONTINUOUS SERVICE: 90°C – IEC 60092-360

SHORT CIRCUIT: 250°C

Notes

* We manufacture with other configurations:

1) The tinned copper conductor can be manufactured in class 2.

2) External cover colors: Nomenclature to be added to the end of the code: VM – Red // VD – Green // BR – White / / PT – Black // AZ – Blue // LJ – Orange

We can manufacture other colors upon request.

3-) Other dimensions: from 1.5mm² to 2.50mm² (Also in AWG).

Other formations up to 71 conductors (see maximum per gauge).

4) Vein insulation material:

EPR – 90 ºC

HEPR – 90 ºC

HF90 – 90 ºC

5) Intermediate cover and cover material:

ST2

SE

SHF2

6) At Innovcable's discretion, separators and/or material fillers may be used compatible.

7) Nomenclature to be added to the end of the code depending on the type of conductor:

Bare copper conductor – CN

Tinned copper conductor – SN

Naval Cables Fire Resistant

**Innovcable reserves the right to change this catalog without prior notice.**

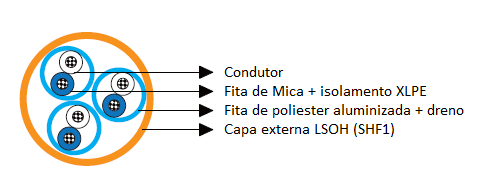

INNOVCABLE INSTRUMENTATION / SHIELDED CONTROL BF- FIRE RESISTANT – MICA TAPE/XLPE/SHF1 – Multi Pair/Triple – 0.15/0.25Kv (300V) – IEC 60331

1) Conductor formed by bare or tinned electrolytic copper wires, soft temper, class 5 stranding. IEC 60228. *1.7

2) Insulation of conductors in mica tape and special halogen-free compound LSOH (XLPE).*4

3 ) Communication conductor with section 0.5mm², in LSOH (HEPR) compound, Identification through blue insulation (only for cables with 2 or more pairs, triples or quads) – (Optional). *4

4) Polyester tape.

5) Collective shielding in aluminum-polyester tape, with flexible drain conductor, formed by tinned electrolytic copper wires, soft temper.

5) Cover in halogen-free polyolefin compound LSOH (SHF1), gray in color. *2.5

Identification

INNOVCABLE INNOVSHORE FIRE RESISTANT INSTRUMENTATION BF XLPE/SHF1 __X__X__mm² 0.15/0.25KV 90°C OF: XXXX/YEAR IEC 60092/60331.

Of the conductors – through the colors of the insulation, being:

black and white (cables in pairs)

black, white and red (cables in bundles).

black, white, red and green (cables in blocks).*3

Identification through sequential numbering.

Applicable Specifications

Applications

Naval Cables Fire Resistant, 90 ° C temperature class, flame retarder (IEC 60332-3), low smoke emission, halogen free, low toxicity and “fire barrier” (IEC 60331, 950 ° C).

Built and designed for the demanding offshore drilling environment and the naval industry. The shield offers protection against electromagnetic interference.

Used on board ships in fixed facilities, trays, gutters, conduits, panels, among others. Suitable for use in control, command and signaling circuits in accordance with IEC 60092-352. Innovshore cables Instrumentation/BF Control 0.15/0.25kV offers maximum resistance to chemicals, humidity and UV rays. Exceed the specifications of the indicated IEC's.

Maximum Conductor Temperature

CONTINUOUS SERVICE: 90°C – IEC 60092-360

SHORT CIRCUIT: 250°C

Notes

* We manufacture with other configurations:

1) The tinned copper conductor can be manufactured in class 2.

2) External cover colors: Nomenclature to be added to the end of the code: VM – Red // VD – Green // BR – White / / PT – Black // AZ – Blue // LJ – Orange

We can manufacture other colors upon request.

3) Different sections and number of veins, maximum up to:

• 71 x 2 x 0.50mm² / 71 x 2 x 2.50mm²

• 71 x 3 x 0.50mm² / 71 x 3 x 2.50mm²

• 36 x 4 x 0 .50mm² / 36 x 4 x 2.50mm²

Also available in AWG.

4) Vein insulation material:

EPR – 90 ºC

HEPR – 90 ºC

HF90 – 90 ºC

5) Intermediate cover and cover material:

ST2

SE

SHF2

6) At Innovcable's discretion, separators and/or material fillers may be used compatible.

7) Nomenclature to be added to the end of the code depending on the type of conductor:

Bare copper conductor – CN

Tinned copper conductor – SN

Naval Cables Fire Resistant

**Innovcable reserves the right to change this catalog without prior notice.**

INNOVCABLE INSTRUMENTATION / SHIELDED CONTROL BFI – FIRE RESISTANT – MICA TAPE/XLPE/SHF1 – Multi Pair/Triple – 0.15/0.25Kv (300V) – IEC 60331

1) Conductor formed by bare or tinned electrolytic copper wires, soft temper, class 5 stranding. IEC 60228. *1.7

2) Insulation of conductors in mica tape and special halogen-free compound LSOH (XLPE).*4

3 ) Communication conductor with section 0.5mm², in LSOH (HEPR) compound, Identification through blue insulation (only for cables with 2 or more pairs, triples or quads) – (Optional). *4

4) Polyester tape.

5) Individual shielding in aluminum-polyester tape, with flexible drain conductor, formed by tinned electrolytic copper wires, soft temper.

6) Cover in halogen-free polyolefin compound LSOH (SHF1), gray in color. *2.5

Identification

INNOVCABLE INNOVSHORE FIRE RESISTANT INSTRUMENTATION BFI XLPE/SHF1 __X__X__mm² 0.15/0.25KV 90°C OF: XXXX/YEAR IEC 60092/60331.

Of the conductors – through the colors of the insulation, being:

black and white (cables in pairs)

black, white and red (cables in bundles).

black, white, red and green (cables in blocks).*3

Identification through sequential numbering.

Applicable Specifications

Applications

Naval Cables Fire Resistant, 90 ° C temperature class, flame retarder (IEC 60332-3), low smoke emission, halogen free, low toxicity and “fire barrier” (IEC 60331, 950 ° C).

Built and designed for the demanding offshore drilling environment and the naval industry. The shield offers protection against electromagnetic interference.

Used on board ships in fixed facilities, trays, gutters, conduits, panels, among others. Suitable for use in control, command and signaling circuits in accordance with IEC 60092-352. Innovshore Cables Instrumentation/BFI Control 0.15/0.25kV offers maximum resistance to chemicals, humidity and UV rays. Exceed the specifications of the indicated IEC's.

Maximum Conductor Temperature

CONTINUOUS SERVICE: 90°C – IEC 60092-360

SHORT CIRCUIT: 250°C

Notes

* We manufacture with other configurations:

1) The tinned copper conductor can be manufactured in class 2.

2) External cover colors: Nomenclature to be added to the end of the code: VM – Red // VD – Green // BR – White / / PT – Black // AZ – Blue // LJ – Orange

We can manufacture other colors upon request.

3) Different sections and number of veins, maximum up to:

• 71 x 2 x 0.50mm² / 71 x 2 x 2.50mm²

• 71 x 3 x 0.50mm² / 71 x 3 x 2.50mm²

• 36 x 4 x 0 .50mm² / 36 x 4 x 2.50mm²

Also available in AWG.

4) Vein insulation material:

EPR – 90 ºC

HEPR – 90 ºC

HF90 – 90 ºC

5) Intermediate cover and cover material:

ST2

SE

SHF2

6) At Innovcable's discretion, separators and/or material fillers may be used compatible.

7) Nomenclature to be added to the end of the code depending on the type of conductor:

Bare copper conductor – CN

Tinned copper conductor – SN

Naval Cables Fire Resistant

**Innovcable reserves the right to change this catalog without prior notice.**

INNOVCABLE INSTRUMENTATION / ARMED CONTROL ATC/ATS- FIRE RESISTANT – MICA TAPE/XLPE/SHF1 – Multi Pair/Triple – 0.15/0.25Kv (300V) – IEC 60331

1) Conductor formed by bare or tinned electrolytic copper wires, soft temper, class 5 stranding. IEC 60228. *1.7

2) Insulation of conductors in mica tape and special halogen-free compound LSOH (XLPE).*4

3 ) Communication conductor with section 0.5mm², in LSOH (HEPR) compound, Identification through blue insulation (only for cables with 2 or more pairs, triples or quads) – (Optional). *4

5) Polyester tape.

6) Frame: Braid of bare copper (ATC) or tinned copper (ATS) wires with >90% coverage. *8

7) Cover in halogen-free polyolefin compound LSOH (SHF1), gray in color. *2.5

Identification

INNOVCABLE INNOVSHORE FIRE RESISTANT INSTRUMENTATION ATC/ATS

Of the conductors – through the colors of the insulation, being:

black and white (cables in pairs)

black, white and red (cables in bundles). *3

black, white, red and green (cables in blocks).

Identification through sequential numbering.

Applicable Specifications

Applications

Naval Cables Fire Resistant, 90 ° C temperature class, flame retarder (IEC 60332-3), low smoke emission, halogen free, low toxicity and “fire barrier” (IEC 60331, 950 ° C).

Built and designed for the demanding offshore drilling environment and the naval industry. The arrow proves protection as required by the standard.

Used on board ships in fixed facilities, trays, gutters, conduits, panels, among others. Suitable for use in control, command and signaling circuits in accordance with IEC 60092-352. Innovshore Cables Control/Instrumentation ATC/ATS 0.15/0.25kV offers maximum resistance to chemicals, humidity and UV rays. Exceed the specifications of the indicated IEC's.

Maximum Conductor Temperature

CONTINUOUS SERVICE: 90°C – IEC 60092-360

SHORT CIRCUIT: 250°C

Notes

* We manufacture with other configurations:

1) The tinned copper conductor can be manufactured in class 2.

2) External cover colors: Nomenclature to be added to the end of the code: VM – Red // VD – Green // BR – White / / PT – Black // AZ – Blue // LJ – Orange

We can manufacture other colors upon request.

3) Different sections and number of veins, maximum up to:

• 71 x 2 x 0.50mm² / 71 x 2 x 2.50mm²

• 71 x 3 x 0.50mm² / 71 x 3 x 2.50mm²

• 36 x 4 x 0 .50mm² / 36 x 4 x 2.50mm²

Also available in AWG.

4) Vein insulation material:

EPR – 90 ºC

HEPR – 90 ºC

HF90 – 90 ºC

5) Intermediate cover and cover material:

ST2

SE

SHF2

6) At Innovcable's discretion, separators and/or material fillers may be used compatible.

7) Nomenclature to be added to the end of the code depending on the type of conductor:

Bare copper conductor – CN

Tinned copper conductor – SN

8) Types of frames:

ATC – Bare copper wire braid frame

ATS – Braid frame of tinned copper wire

Naval Cables Fire Resistant

**Innovcable reserves the right to change this catalog without prior notice.**

INNOVCABLE INSTRUMENTATION / ARMED CONTROL ATC/ATS- FIRE RESISTANT – MICA TAPE/HEPR/SHF1 – Multi Pair/Triple – 0.15/0.25Kv (300V) – IEC 60331

1) Conductor formed by bare or tinned electrolytic copper wires, soft temper, class 5 stranding. IEC 60228. *1.7

2) Insulation of conductors in mica tape and special halogen-free compound LSOH (HEPR).*4

3 ) Communication conductor with section 0.5mm², in LSOH (HEPR) compound, Identification through blue insulation (only for cables with 2 or more pairs, triples or fours) – (Optional). *4

5) Polyester tape.

6) Frame: Braid of bare copper (ATC) or tinned copper (ATS) wires with >90% coverage. *8

7) Cover in halogen-free polyolefin compound LSOH (SHF1), gray in color. *2.5

Identification

INNOVCABLE INNOVSHORE FIRE RESISTANT INSTRUMENTATION ATC/ATS HEPR/SHF1 __X__X__mm² 0.15/0.25KV 90°C OF: XXXX/YEAR IEC 60092/60331.

Of the conductors – through the colors of the insulation, being:

black and white (cables in pairs)

black, white and red (cables in bundles).

black, white, red and green (cables in blocks).*3

Identification through sequential numbering.

Applicable Specifications

Applications

Naval Cables Fire Resistant, 90 ° C temperature class, flame retarder (IEC 60332-3), low smoke emission, halogen free, low toxicity and “fire barrier” (IEC 60331, 950 ° C).

Built and designed for the demanding offshore drilling environment and the naval industry. The arrow proves protection as required by the standard.

Used on board ships in fixed facilities, trays, gutters, conduits, panels, among others. Suitable for use in control, command and signaling circuits in accordance with IEC 60092-352. Innovshore Cables Control/Instrumentation ATC/HEPR 0.15/0.25kV offers maximum resistance to chemicals, humidity and UV rays. Exceed the specifications of the indicated IEC's.

Maximum Conductor Temperature

CONTINUOUS SERVICE: 90°C – IEC 60092-360

SHORT CIRCUIT: 250°C

Notes

* We manufacture with other configurations:

1) The tinned copper conductor can be manufactured in class 2.

2) External cover colors: Nomenclature to be added to the end of the code: VM – Red // VD – Green // BR – White / / PT – Black // AZ – Blue // LJ – Orange

We can manufacture other colors upon request.

3) Different sections and number of veins, maximum up to:

• 71 x 2 x 0.50mm² / 71 x 2 x 2.50mm²

• 71 x 3 x 0.50mm² / 71 x 3 x 2.50mm²

• 36 x 4 x 0 .50mm² / 36 x 4 x 2.50mm²

Also available in AWG.

)

Vein insulation material:

EPR –

90

ºC

HF90 –

90 ºC compatible. 7) Nomenclature to be added to the end of the code depending on the type of conductor:

Bare copper conductor – CN

Tinned copper conductor – SN

8) Types of frames:

ATC – Bare copper wire braid frame

ATS – Braid frame of tinned copper wire

Naval Cables Fire Resistant

**Innovcable reserves the right to change this catalog without prior notice.**

INNOVCABLE INSTRUMENTATION / ARMED CONTROL / ARMORED ATC/ATS BF- FIRE RESISTANT – MICA TAPE/XLPE/SHF1 – Multi Pair/Triple – 0.15/0.25Kv (300V) – IEC 60331

1) Conductor formed by bare or tinned electrolytic copper wires, soft temper, class 5 stranding. IEC 60228. *1.7

2) Insulation of conductors in mica tape and special halogen-free compound LSOH (XLPE).*4

3 ) Communication conductor with section 0.5mm², in LSOH (HEPR) compound, Identification through blue insulation (only for cables with 2 or more pairs, triples or quads) – (Optional). *4

4) Collective shielding in aluminum-polyester tape, with flexible drain conductor, formed by tinned electrolytic copper wires, soft temper.

5) Polyester tape.

6) Frame: Braid of bare copper (ATC) or tinned copper (ATS) wires with >90% coverage. *8

7) Cover in halogen-free polyolefin compound LSOH (SHF1), gray in color. *2.5

Identification

INNOVCABLE INNOVSHORE FIRE RESISTANT INSTRUMENTATION ATC/ATS BF XLPE/SHF1 __X__X__mm² 0.15/0.25KV 90°C OF: XXXX/YEAR IEC 60092/60331.

Of the conductors – through the colors of the insulation, being:

black and white (cables in pairs)

black, white and red (cables in bundles).

black, white, red and green (cables in blocks).*3

Identification through sequential numbering.

Applicable Specifications

Applications

Naval Cables Fire Resistant, 90 ° C temperature class, flame retarder (IEC 60332-3), low smoke emission, halogen free, low toxicity and “fire barrier” (IEC 60331, 950 ° C).

Built and designed for the demanding offshore drilling environment and the naval industry. The shield offers protection against electromagnetic interference and the prove protection frame as required by the standard.

Used on board ships in fixed facilities, trays, gutters, conduits, panels, among others. Suitable for use in control, command and signaling circuits in accordance with IEC 60092-352. Innovshore Cables Control/Instrumentation ATC/ATS BF 0.15/0.25kV offers maximum resistance to chemicals, humidity and UV rays. Exceed the specifications of the indicated IEC's.

Maximum Conductor Temperature

CONTINUOUS SERVICE: 90°C – IEC 60092-360

SHORT CIRCUIT: 250°C

Notes

* We manufacture with other configurations:

1) The tinned copper conductor can be manufactured in class 2.

2) External cover colors: Nomenclature to be added to the end of the code: VM – Red // VD – Green // BR – White / / PT – Black // AZ – Blue // LJ – Orange

We can manufacture other colors upon request.

3) Different sections and number of veins, maximum up to:

• 71 x 2 x 0.50mm² / 71 x 2 x 2.50mm²

• 71 x 3 x 0.50mm² / 71 x 3 x 2.50mm²

• 36 x 4 x 0 .50mm² / 36 x 4 x 2.50mm²

Also available in AWG.

4) Vein insulation material:

EPR – 90 ºC

HEPR – 90 ºC

HF90 – 90 ºC

5) Intermediate cover and cover material:

ST2

SE

SHF2

6) At Innovcable's discretion, separators and/or material fillers may be used compatible.

7) Nomenclature to be added to the end of the code depending on the type of conductor:

Bare copper conductor – CN

Tinned copper conductor – SN

8) Types of frames:

ATC – Bare copper wire braid frame

ATS – Braid frame of tinned copper wire

Naval Cables Fire Resistant

**Innovcable reserves the right to change this catalog without prior notice.**

INNOVCABLE INSTRUMENTATION / ARMED CONTROL / ARMORED ATC/ATS BFI – FIRE RESISTANT – MICA TAPE/XLPE/SHF1 – Multi Pair/Triple – 0.15/0.25Kv (300V) – IEC 60331

1) Conductor formed by bare or tinned electrolytic copper wires, soft temper, class 5 stranding. IEC 60228. *1.7

2) Insulation of conductors in mica tape and special halogen-free compound LSOH (XLPE).*4

3 ) Communication conductor with section 0.5mm², in LSOH (HEPR) compound, Identification through blue insulation (only for cables with 2 or more pairs, triples or quads) – (Optional). *4

4) Individual shielding in aluminum-polyester tape, with flexible drain conductor, formed by tinned electrolytic copper wires, soft temper.

5) Polyester tape.

6) Frame: Braid of bare copper (ATC) or tinned copper (ATS) wires with >90% coverage. *8

7) Cover in halogen-free polyolefin compound LSOH (SHF1), gray in color. *2.5

Identification

INNOVCABLE INNOVSHORE FIRE RESISTANT INSTRUMENTATION ATC/ATS BFI XLPE/SHF1 __X__X__mm² 0.15/0.25KV 90°C OF: XXXX/YEAR IEC 60092/60331.

Of the conductors – through the colors of the insulation, being:

black and white (cables in pairs)

black, white and red (cables in bundles).

black, white, red and green (cables in blocks).*3

Identification through sequential numbering.

Applicable Specifications

Applications

Naval Cables Fire Resistant, 90 ° C temperature class, flame retarder (IEC 60332-3), low smoke emission, halogen free, low toxicity and “fire barrier” (IEC 60331, 950 ° C).

Built and designed for the demanding offshore drilling environment and the naval industry. The shield offers protection against electromagnetic interference and the prove protection frame as required by the standard.

Used on board ships in fixed facilities, trays, gutters, conduits, panels, among others. Suitable for use in control, command and signaling circuits in accordance with IEC 60092-352. Innovshore Cables Control/Instrumentation ATC/ATS BFI 0.15/0.25kV offers maximum resistance to chemicals, humidity and UV rays. Exceed the specifications of the indicated IEC's.

Maximum Conductor Temperature

CONTINUOUS SERVICE: 90°C – IEC 60092-360

SHORT CIRCUIT: 250°C

Notes

* We manufacture with other configurations:

1) The tinned copper conductor can be manufactured in class 2.

2) External cover colors: Nomenclature to be added to the end of the code: VM – Red // VD – Green // BR – White / / PT – Black // AZ – Blue // LJ – Orange

We can manufacture other colors upon request.

3) Different sections and number of veins, maximum up to:

• 71 x 2 x 0.50mm² / 71 x 2 x 2.50mm²

• 71 x 3 x 0.50mm² / 71 x 3 x 2.50mm²

• 36 x 4 x 0 .50mm² / 36 x 4 x 2.50mm²

Also available in AWG.

4) Vein insulation material:

EPR – 90 ºC

HEPR – 90 ºC

HF90 – 90 ºC

5) Intermediate cover and cover material:

ST2

SE

SHF2

6) At Innovcable's discretion, separators and/or material fillers may be used compatible.

7) Nomenclature to be added to the end of the code depending on the type of conductor:

Bare copper conductor – CN

Tinned copper conductor – SN

8) Types of frames:

ATC – Bare copper wire braid frame

ATS – Braid frame of tinned copper wire

Naval Cables Fire Resistant

**Innovcable reserves the right to change this catalog without prior notice.**

Research and Knowledge Centers

InnovCable: cutting -edge engineering for the challenges of tomorrow

For engineers, researchers and students who are not content with the standard, InnovCable is positioned not only as a cable manufacturer, but as a technological partner at the forefront of innovation . We understand that in sectors such as naval and oil and gas, a cable is not just a component; It is a vital line, the backbone of complex operations that occur in the most severe environments on the planet.

This is why our commitment to cutting -edge research is the core of everything we do.

How InnovCable stands out and innovates:

- Strategic collaboration with the Academy and Institutes: We do not expect the future, we build it together. Innovcable maintains active partnerships with late universities such as USP, Unicamp and Unifei , and constantly dialogues with the challenges presented by centers such as Cenpes and Cepel . We finance master and doctoral projects focused on solving real problems, such as the development of new insulating materials resistant to H₂S gas degradation or modeling of umbilical cable behavior under extreme fatigue.

- Advanced Materials Engineering: Our laboratories go beyond compliance tests. We actively researched and developed high performance elastomeric compounds, capable of supporting abyssal pressure, saline corrosion and temperatures ranging from Arctic to Equatorial. We are pioneers in the application of LSZH compounds (Low Smoke Zero Halogen) Mud-Resistant cable lines are designed to resist the chemical attack of drilling fluids, ensuring circuit integrity for decades.

- Digitization and Industry 4.0 in cables: We see each cable as a smart asset. Innovcable is at the forefront of integration of fiber optic sensors (DSS/DAS) in power and umbilical cables. This allows real -time monitoring of structural integrity, temperature and vibration throughout its extent. For an operations engineer, this means the transition from corrective maintenance to predictive maintenance , avoiding catastrophic failures and optimizing production. We created digital twins of our solutions, allowing accurate simulations that accelerate commissioning and increase project reliability.

- Overcoming standards through innovation: For InnovCable, certifications from entities such as DNV, ABS and Bureau Veritas are not the ultimate goal, but the starting point. Our R&D team analyzes the most strict requirements and develops solutions that outweigh them, offering safety and reliability margins that give our customers peace of mind. When a new challenge arises, such as electrifying platforms to reduce emissions, our engineering team is already working with technical committees to develop high power cables that will make this vision a safe and efficient reality.

For professionals and future engineers seeking to leave their brand, InnovCable offers more than one product: we offer an invitation to solve industry's most difficult problems by connecting the future of energy and navigation with intelligence, safety and a tireless spirit of innovation.

Innovcable Knowledge Bases

- Knowledge Academy: Application and Installation of Moveable Cables - Rolante Bridge, Currency, Festoons, Elevators, Crane Treadmills…

- InnovCable Furniture Guide: What mobile cables do you use?

- Why use InnovCable Mobile Cables: Considerations of why utilize mobile cables

- Cable storage and transportation guidelines

- GLOSSARY: Technical Terms in English

- Color Code Tables: According to DIM47100, BS4737, BS5308

- Copper Temperature Coefficients: Constant to convert resistance at various temperatures to the standard 20 ° CE reference temperature of constants to convert resistance to 20 ° C other temperatures.

- MISCELLANEOUS METAL DATA

- Tables: Cenelec - VDE

- Dimensioning tables: power cables - NBR 5410

- COMPENSATION AND EXTENSION THERMOCOUPLE CABLES AND WIRE TABLES

- Driver Class : mm² x AWG

- Diverse technical information

- Naval cable codes and nomenclatures as per Nek606

- SHF1 AND SHF2 COVERS ACCORDING TO NEK-606

- Resistance of insulation and cover materials, comparative of properties

- Resistance from Armação / Armor Resistance

- Current classifications and voltage drop vol 1 - IEE

- Current classifications and voltage drop Vol 2 - IEE

- Fire Performance Standards: Fire Performance Cable Standards

- Radius of minimum allowed curvature: according to DIN VDE 0298 PART 3

- STANDARDS

- Voltage Fall Calculations: VoltaGe Drop Calculations

Knowledge Bases and Core Topics

This section covers the theoretical and practical pillars of marine and oil & gas engineering.

- HYDROSTATICS AND STABILITY: Principles of buoyancy, intact and damaged stability criteria (SOLAS, IMO).

- HYDRODYNAMICS AND OFFSHORE ENGINEERING: Resistance to progress, propulsion, maneuverability, behavior at sea ( seakeeping ), and analysis of anchoring systems and dynamic positioning.

- NAVAL AND OFFSHORE STRUCTURES: Structural analysis of hulls and platforms (fixed and floating). Fatigue, vibration and response to environmental loads.

- NAVAL AND SUBSEA MACHINES AND SYSTEMS: Propulsion systems, power generation, subsea production systems, umbilicals and risers .

- O&G DESIGN AND TECHNOLOGY: Exploration, drilling and production technologies in deep and ultra-deep waters.

- SAFETY AND REGULATION: Study of international conventions (SOLAS, MARPOL) and the rules of classification societies and regulatory bodies (ANP, DPC).

- MATERIALS AND CORROSION: Naval steels, special alloys, composite materials and corrosion protection technologies in marine environments.

Databases and academic search mechanisms

Essential for researching scientific articles, theses and dissertations.

- IEEE Xplore Digital Library: IEEE

- ACM Digital Library: ACM

- ScienceDirect: SCIENCE DIRECT

- Scopus: SCOPUS

- CAPES Journal Portal: CAPES

- Google Scholar: GOOGLE SCHOLAR

Prominent journals and journals

- Ocean Engineering (Elsevier)

- Journal of Ship Research (SNAME)

- Journal of Petroleum Science and Engineering (Elsevier)

- Journal of Marine Science and Engineering (MDPI)

- Journal of the Brazilian Society of Naval Engineering (SOBENA)

Classification and Certification Societies

Entities that create rules and certify that ships, platforms and equipment are designed, built and maintained safely.

- DNV (Det Norske Veritas): DNV – A world leader and undisputed benchmark in the energy and maritime sectors. Its standards for offshore systems are a global standard.

- ABS (American Bureau of Shipping): ABS – A highly prestigious classification body, with a strong presence in O&G projects and a pioneer in rules for new technologies.

- Lloyd's Register (LR): LR – One of the oldest and most respected, with extensive experience in compliance verification and risk analysis for the energy chain.

- Bureau Veritas (BV): Bureau Veritas – A world leader in testing, inspection and certification (TIC), with a robust marine and offshore division.

- RINA (Registro Italiano Navale): RINA – Founded in 1861, it is a global reference in certification and engineering consultancy for the naval and energy sectors.

- ClassNK (Nippon Kaiji Kyokai): ClassNK – Japan’s main classifying agency and one of the largest in the world.

- IACS (International Association of Classification Societies): IACS – Brings together the main societies to establish unified technical standards.

Technical Standards and Regulatory Entities

- IMO (International Maritime Organization): IMO – UN agency that develops global conventions for maritime safety and pollution prevention (SOLAS, MARPOL).

- ANP (National Agency of Petroleum, Natural Gas and Biofuels): ANP – Regulatory body for the activities of the O&G industries in Brazil, essential for the technical and safety regulation of assets.

- DPC (Directorate of Ports and Coasts): DPC – Brazilian Maritime Authority (Brazilian Navy) that establishes the standards (NORMAM) for vessels and platforms.

- API (American Petroleum Institute): API – Main association of the US O&G industry, which establishes technical standards recognized and used worldwide.

- ABNT (Brazilian Association of Technical Standards): ABNT Catalog – Responsible for technical standardization in Brazil.

Research Giants: Top Universities

National scenario

- University of São Paulo (USP – Naval Engineering): The Polytechnic School has one of the most traditional Naval and Ocean Engineering departments in the country, conducting research in hydrodynamics, structures and vessel design.

- Federal University of Rio de Janeiro (UFRJ – Ocean Engineering): Home to the Ocean Engineering Program and LabOceano , the deepest ocean tank in the world, a global reference for testing offshore systems.

- State University of Campinas (Unicamp): Although it does not offer a naval course, FEM and FEEC are references in mechanical, materials and electrical engineering, with research applicable to naval machines and systems.

International scenario

- NTNU (Norwegian University of Science and Technology): NTNU – Considered one of the best in the world in marine engineering, it is a center of innovation in subsea technology.

- TU Delft (Delft University of Technology) – Netherlands: TU Delft – Powerhouse in Offshore, Dredging and Maritime Engineering.

- University of Strathclyde (UK): Strathclyde NAOME – Department of Naval Architecture, Ocean and Marine Engineering, leading in Europe.

- Texas A&M University (USA): Recognized worldwide for its Petroleum Engineering program , covering the full range of E&P technologies.

- Heriot-Watt University (UK): Its Institute of GeoEnergy Engineering is a global center of excellence for teaching and research in oil and gas and the energy transition.

- University of Michigan – USA: UMich Naval Architecture – One of the most prestigious naval architecture and marine engineering schools in the USA.

Research and Innovation Institutes

National scenario

- CENPES (Petrobras Research, Development and Innovation Center): CENPES – The technological brain of Petrobras, one of the largest energy research centers in the world, focusing on deepwater technologies.

- IPT (Technological Research Institute): IPT – Performs complex tests, material analysis and development of engineering solutions for large naval and O&G structures.

- SENAI CIMATEC: SENAI CIMATEC – Advanced technology and innovation center that works strongly with the O&G industry in robotics, automation and supercomputing.

- CEPEL (Electric Energy Research Center): CEPEL – Crucial for the offshore sector, researching equipment for subsea electrical systems and energy integration on platforms.

- IPqM (Navy Research Institute): IPqM – Develops military application technologies for the Brazilian Navy, such as underwater acoustics and combat systems.

International scenario

- SINTEF – Norway: SINTEF – One of Europe’s largest independent research institutes, conducting applied research for the energy and ocean sectors.

- MARIN (Maritime Research Institute Netherlands) – Netherlands: MARIN – Global leader in experimental and numerical hydrodynamics research.

- TNO (Netherlands Organisation for Applied Scientific Research) – Netherlands: TNO – Develops innovative solutions in partnership with industry, including monitoring of offshore structures and sustainable energy systems at sea.

- HSVA (Hamburg Ship Model Basin) – Germany: HSVA – World reference in ship model testing and, especially, in ice hydrodynamics.