INNOVCABLE EXTREME FIRE RESISTANT CONTROL SHIELD – IEC60331 – 0.6/1KV

Fire system cables – extreme fire resistant

INNOVCABLE EXTREME FIRE RESISTANT POWER – IEC60331 – 0.6/1KV

1 -) Conductor: bare copper wires twisted in layer, class 2 – NM-280.

2 -) Fire Barrier: Fire resistant mineral ceramic. IEC 60331

3 -) Insulation: Special cross-linked polyethylene (XLPE) 90ºC

Insulation color:

1 conductor: Natural.

2 conductors: Natural and Black.

3 conductors: Natural, Black and Red.

4 conductors: Natural, Black, Red and Green.

4 -) Special Polyester Ribbon.

5 -) External Cover: LSZH compound, low smoke emission and halogen-free, orange color.

– Test voltage: 3.5KV

Identification

INNOVCABLE EXTREME FIRE RESISTANT POWER – IEC 60331 – _ x _mm² _0.6/1KV – 90ºC – OF XXXX: YEAR

Applicable Specifications

Applications

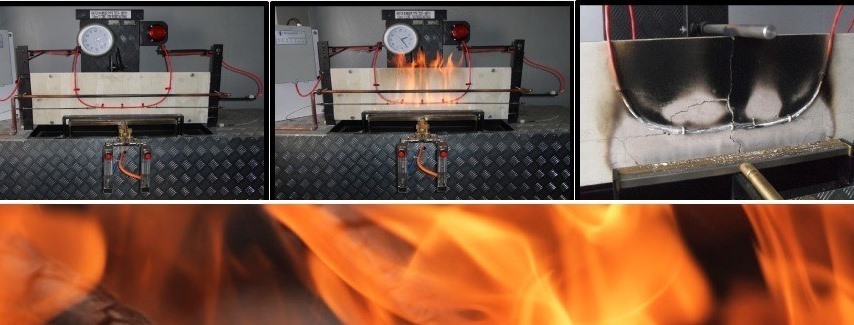

Extreme Fire Resistant Cables are designed for exceptional performance under flame. Tested in accordance with IEC 60331, these cables can withstand flames of 750ºC for at least 180 minutes without short circuits and with continuity integrity (0.25mA). Cables that protect lives and assets at the highest level of innovation and technology. They are used successfully in many applications such as foundries, steel factories, glass production, chemical industry, military field, among others, it is also used in areas where, in case of fire, all types of vital equipment need to remain operational . The cable's excellent fire performance allows extra time for equipment to be saved or shut down, thus limiting unnecessary damage. It also has obvious advantages over high-temperature cable types. With a life cycle that is 5 times longer than other high temperature cables, replacement of these cables is less frequent. This offers considerable cost savings along with reduced threat of degradation situations and production loss. They do not contain asbestos and are unable to spread fire. They are flame retardant and highly temperature resistant. Low installation and operating costs.

Due to their extreme high temperature performance, experience has shown that they can often be installed completely exposed. This makes installation quicker and means the cable can be easily inspected, so damage can be easily found.

Use and specify INNOVCABLE EXTREME FIRE RESISTANT – IEC 60331 cables in your project.

Maximum Conductor Temperature

+ 90ºC, for circuit voltages (U) that do not exceed 1,200 volts.

Notes

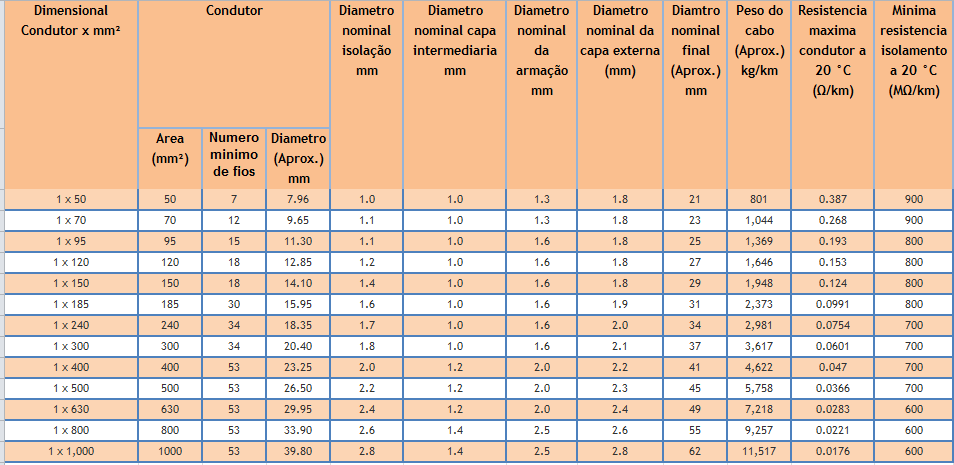

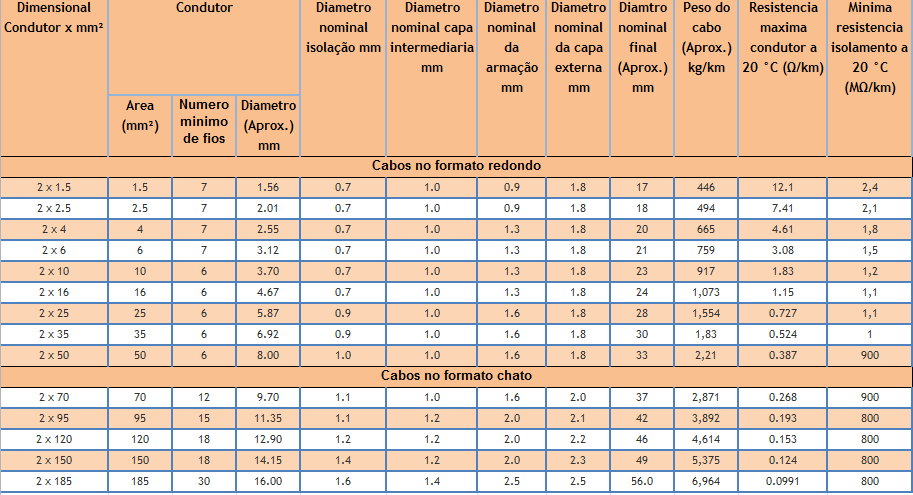

Unipolar cables are all round in shape.

Multiple cables with 2, 3 and 4 conductors up to 50.0mm² are built in a round shape, above this gauge they are built in a flat shape.

WE CAN MANUFACTURE OTHER CONFIGURATIONS ON REQUEST:

1- Tinned copper conductor.

Stringing class 1, 4 or 5.

2- Insulation material for veins / other temperatures.

Innovcable reserves the right to change this catalog without prior notice.

INNOVCABLE EXTREME FIRE RESISTANT CONTROL SHIELD – IEC60331 – 0.6/1KV

1 -) Conductor: bare copper wires twisted in layer, class 2 – NM-280.

2 -) Fire Barrier: Fire resistant mineral ceramic. IEC 60331

3 -) Insulation: Special cross-linked polyethylene (XLPE) 90ºC, black or white colors numbered sequentially.

4 -) Filament (filler) in LSZH compound, low smoke emission and halogen-free

5 -) Special Polyester Tape (if necessary)

6 -) Intermediate Cover: LSZH compound, low smoke emission and halogen-free.

7 -) Copper tape shielding.

8 -) Special Polyester Tape (if necessary)

9 -) Outer Cover: LSZH compound, low smoke emission and halogen free, orange color.

– Test voltage: 3.5KV

Identification

INNOVCABLE EXTREME FIRE RESISTANT CONTROL SHIELD – IEC 60331 – _ x _mm² _0.6/1KV – 90ºC – OF XXXX: YEAR

Applicable Specifications

Applications

Extreme Fire Resistant Cables are designed for exceptional performance under flame. Tested in accordance with IEC 60331, these cables can withstand flames of 750ºC for at least 180 minutes without short circuits and with continuity integrity (0.25mA). Cables that protect lives and assets at the highest level of innovation and technology. They are used successfully in many applications such as foundries, steel factories, glass production, chemical industry, military field, among others, it is also used in areas where, in case of fire, all types of vital equipment need to remain operational . The cable's excellent fire performance allows extra time for equipment to be saved or shut down, thus limiting unnecessary damage. It also has obvious advantages over high-temperature cable types. With a life cycle that is 5 times longer than other high temperature cables, replacement of these cables is less frequent. This offers considerable cost savings along with reduced threat of degradation situations and production loss. They do not contain asbestos and are unable to spread fire. They are flame retardant and highly temperature resistant. Low installation and operating costs.

Due to their extreme high temperature performance, experience has shown that they can often be installed completely exposed. This makes installation quicker and means the cable can be easily inspected, so damage can be easily found.

Use and specify INNOVCABLE EXTREME FIRE RESISTANT – IEC 60331 cables in your project.

Maximum Conductor Temperature

+ 90ºC, for circuit voltages (U) that do not exceed 1,200 volts.

Notes

WE CAN MANUFACTURE OTHER CONFIGURATIONS ON REQUEST:

1- Tinned copper conductor.

Stringing class 1, 4 or 5.

2- Insulation material for veins / other temperatures.

Innovcable reserves the right to change this catalog without prior notice.

INNOVCABLE EXTREME FIRE RESISTANT POWER ARMOR – IEC60331 – 0.6/1KV

1 -) Conductor: bare copper wires twisted in layer, class 2 – NM-280.

2 -) Fire Barrier: Fire resistant mineral ceramic. IEC 60331

3 -) Insulation: Special cross-linked polyethylene (XLPE) 90ºC

Insulation color:

1 conductor: Natural.

2 conductors: Natural and Black.

3 conductors: Natural, Black and Red.

4 conductors: Natural, Black, Red and Green.

4 -) Filament (filler) in LSZH compound, low smoke emission and halogen-free

5 -) Special Polyester Tape.

6 -) Intermediate Cover: LSZH compound, low smoke emission and halogen-free.

7 -) Frame in galvanized steel wires.

8 -) External Cover: LSZH compound, low smoke emission and halogen-free, orange color.

– Test voltage: 3.5KV

Identification

INNOVCABLE EXTREME FIRE RESISTANT POWER ARMOR – IEC 60331 – _ x _mm² _0.6/1KV – 90ºC – OF XXXX: YEAR

Applicable Specifications

Applications

Extreme Fire Resistant Cables are designed for exceptional performance under flame. Tested in accordance with IEC 60331, these cables can withstand flames of 750ºC for at least 180 minutes without short circuits and with continuity integrity (0.25mA). Cables that protect lives and assets at the highest level of innovation and technology. They are used successfully in many applications such as foundries, steel factories, glass production, chemical industry, military field, among others, it is also used in areas where, in case of fire, all types of vital equipment need to remain operational . The cable's excellent fire performance allows extra time for equipment to be saved or shut down, thus limiting unnecessary damage. It also has obvious advantages over high-temperature cable types. With a life cycle that is 5 times longer than other high temperature cables, replacement of these cables is less frequent. This offers considerable cost savings along with reduced threat of degradation situations and production loss. They do not contain asbestos and are unable to spread fire. They are flame retardant and highly temperature resistant. Low installation and operating costs.

Due to their extreme high temperature performance, experience has shown that they can often be installed completely exposed. This makes installation quicker and means the cable can be easily inspected, so damage can be easily found.

Use and specify INNOVCABLE EXTREME FIRE RESISTANT – IEC 60331 cables in your project.

Maximum Conductor Temperature

+ 90ºC, for circuit voltages (U) that do not exceed 1,200 volts.

Notes

Unipolar cables are all round in shape.

Multiple cables with 2, 3 and 4 conductors up to 50.0mm² are built in a round shape, above this gauge they are built in a flat shape.

WE CAN MANUFACTURE OTHER CONFIGURATIONS ON REQUEST:

1- Tinned copper conductor.

Stringing class 1, 4 or 5.

2- Insulation material for veins / other temperatures.

Innovcable reserves the right to change this catalog without prior notice.

INNOVCABLE EXTREME FIRE RESISTANT JE-H(St)H FE180 E30-E90 – IEC60331

1. Conductor: solid copper 0.8 mm Ø

2. Insulation: mica ceramic insulated with polymeric compound cross-linked, cross-linked, LSZH, halogen-free

3. Twist:

a) 2 conductors forming a pair

b) 4 pairs forming a bundle

c) bundles assembled in layers

4. Polyester tape applied helically.

5. Shielding in aluminized polyester tape + 0.8 mm drain conductor Ø

6. External cover: halogen-free polymeric compound LSZH in orange, or in Red when (BMK).

– Operating voltage: max. 225 V

-Voltage test:

conductor – conductor: 500 V

conductor – outer cover: 2000 V

– Circuit resistance: 20°C: max. 73.2 Ω/km

– Insulation Resistance: min. 100 MΩxkm

– Mutual capacitance: (at 800 Hz) max. 1201) nF/km

– Mutual capacitance: (at 800 Hz) max. 200 pF/100m

– Inductance: 0.65 mH/km

– Linear attenuation: (at 800 Hz) approx. 1.2 dB/km

Identification

Each bundle:

Pair 1: blue – red

Pair 2: gray – yellow

Pair 3: green – brown

Pair 4: white – black

Individual bundles are identified by numbered tape.

Applicable Specifications

Applications

Halogen-free installation cable for industrial electronics, with improved properties under fire, applied in measurement, data and control systems. Electrostatic shielding protects transmission circuits against external disruptive electromagnetic impacts. Suitable for fixed installation in dry or damp locations where people and material assets need to be protected in the event of fire. Recommended for public and industrial installations where there are crowds of people, and for installations of high-value assets. It should not be applied directly to soil or water, should not be used outdoors (except when adequately protected from sunlight), and should not be used as a supply. The cable is safe in the 180 minute test (acc) – the insulation remains compact under the impact of the open flame throughout the entire 180 minute test period. Circuit integrity retained 30 or 90 minutes, depending on installation technique.

E30: The cable allows circuit integrity for 30 minutes under fire, sufficient to evacuate people and animals from the building under fire. During the 30-minute period, it allows the operation of alarm systems, panic lighting, passenger elevators for evacuation, except for cables installed in shaft stairs and machine rooms.

E90: The cable allows a circuit integrity of 90 minutes under fire, in submarine stations under increased pressure in order to avoid smoke and temperature increase in security stages and internal rooms, shaft ladders and machine rooms, elevators for brigades fire fighting systems and hospital elevators.

Maximum Conductor Temperature

During installation: -5°C to +50°C

Fixed installed: -30°C to +70°C

Notes

WE CAN MANUFACTURE OTHER CONFIGURATIONS ON REQUEST:

1- Tinned copper conductor.

2- Other stringing classes

3- Vein insulation material / other temperatures.

Innovcable reserves the right to change this catalog without prior notice