KNOWLEDGE ACADEMY

Power cable sizing tables – NBR 5410

Explanation

• Definitions:

Insulated conductor: conductor provided with only insulation.

Unipolar cable: cable consisting of a single insulated conductor and provided with a covering over the insulation.

Multipolar cable: cable made up of several insulated conductors and provided with a covering over all of the insulated conductors.

• Conduits:

Insulated conductors, unipolar or multipolar cables can be installed in conduits. The use of a bare conductor in conduits is only permitted when in exclusive insulating conduit and for grounding purposes.

• Outdoor installations

Outdoor installations are considered to be those on trays, beds, shelves, supports or directly fixed to walls or ceilings.

In outdoor installations, only single-core or multi-core cables may be installed.

• Cable rails:

Insulated conductors, single-core or multi-core cables can be installed in cable trays.

• Directly buried cables:

Directly buried cables can only be single-core or multi-core and measures must be taken to protect them against deterioration caused by earth movement, shock from excavation tools and chemical attacks or humidity.

• Channels in the ground:

Cables installed directly in ground channels can only be unipolar or multipolar or the use of insulated conductors is permitted as long as they are contained in conduits inside the channel.

• About insulators:

Bare, isolated or bundled conductors can be used on insulators.

Power Cable Sizing Recommendations

1-)Get to know the installation

- Type of installation (underground, overhead, ducts, gutters, etc.)

- Current to be transported

- Electrical voltage of the circuit

- Distance

- power factor

- What is the power source (direct or indirect)

- Power destination (motor, bus, oven, etc.)

- How many conductors per phase

- Type of system (single-phase or three-phase)

- Current type (AC or DC)

2-) Calculate the ampacity and voltage drop

- Check the additions in the chain to be considered, i.e. grouping factor, etc.

- Check the MBR 5410 table for the maximum current per section, depending on the installation conditions.

- Assess the maximum voltage drop

- Extract the values of Rca and XL (AC electrical resistance and inductive reactance)

- Consider the values of CosY and SenY (power factor)

3-) Adapt to voltage drop limits

- D value , divide by the system voltage;

- Consider limits of up to 4% voltage drop for customers who receive power from utility lines or up to 7% for customers who have their own power supply such as transformers and substations.

Table 1- Installation methods

Table 2 - Current carrying capacities, in amps, for reference methods A1, A2, B1, B2, C and D in table 1.

2 and 3 loaded conductors.

- Conductor temperature = 70ºC

- Ambient temperature = 30ºC and soil temperature = 20ºC

Table 2A - Current carrying capacities, in amps, for reference methods A1, A2, B1, B2, C and D in table 1.

2 and 3 loaded conductors.

- Conductor temperature = 90ºC

- Ambient temperature = 30ºC and soil temperature = 20ºC

Table 3 - Current carrying capacities, in amps, for reference methods e, f, g in table 1.

2 and 3 loaded conductors.

- Conductor temperature = 70ºC

- Ambient temperature = 30ºC and soil temperature = 20ºC

Table 3A - Current carrying capacities, in amps, for the reference methods e, f, g of Table 1.

2 and 3 loaded conductors.

- Conductor temperature = 90ºC

- Ambient temperature = 30ºC and soil temperature = 20ºC

Table 4 - Correction factors for ambient temperatures different from 30 ºC for unburied cables and 20 ºC (soil temperature) for buried cables.

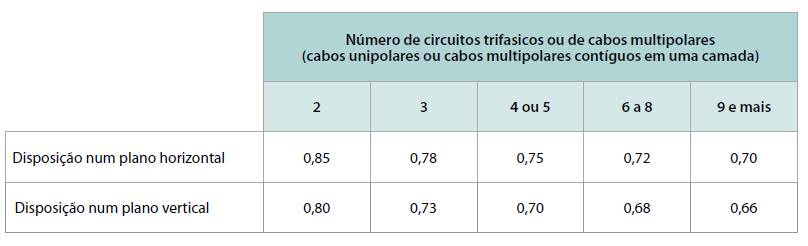

Table 5 - Correction factors for grouping circuits or multipolar cables.

Notes:

a) These factors are applicable to groups of cables, uniformly loaded.

b) When the horizontal distance between adjacent cables is greater than twice their external diameter, it is not necessary to apply any correction factor.

c) The same correction factors are applicable to: (1) groups of 2 or 3 insulated conductors or unipolar cables; (2) multi-core cables.

d) If a bundle consists of both two-pole and three-core cables, the total number of cables is taken equal to the number of circuits and the corresponding correction factor is applied to the 3-conductor tables loaded for three-core cables.

e) If a grouping consists of N insulated conductors or unipolar cables, either N/2 circuits with 2 loaded conductors or N/3 circuits with 3 loaded conductors can be considered.

f) The values indicated are average for the usual range of nominal sections, with an accuracy of ± 5%.

g) The correction factors in items 4 and 5 are generic and may not meet specific situations. In these cases, tables 10 and 11 must be used.

Table 6 - Correction factors for cables contained in conduits buried in the ground, with thermal resistivities different from 2.5 Km/W, to be applied to the current conduction capabilities of reference method D.

Table 7 - Correction factors for groupings with more than one circuit of single-core cables or directly buried multi-core cables (installation method D in table 1.

Table 8 - Multipliers to be used to obtain the grouping factors applicable to three-phase circuits or multi-pole cables outdoors, contiguous cables, in several horizontal layers, on trays, shelves and horizontal supports (installation methods C, E, F of table 1)

Table 9 - Correction factors for groupings with more than one cable circuit in directly buried conduits (installation method D in table 1)

a) Multipolar cables in conduits (ducts) 1 cable per conduit (duct)

b) Unipolar cables in conduits (ducts) 1 cable per conduit (duct)

Table 10 - Correction factors for bundlings of more than one outdoor multicore cable, (installation method E in table 1)

Notes:

a) The values indicated are averages for the types of cables and the range of sections in table 3.

b) The factors are applicable to cables grouped in a single layer, as shown above, and do not apply to cables arranged in more than one layer. The values for such provisions may be significantly lower and must be determined by an appropriate method; table 8 can be used.

c) The values are indicated for a vertical distance between trays or beds of 300 mm. For shorter distances, the factors must be reduced.

d) The values are indicated for a horizontal distance between trays of 225 mm, when these are mounted bottom to bottom. For smaller spacings, the factors must be reduced.

Table 11 - Correction factors for the grouping of circuits consisting of outdoor single-core cables (installation method F in table 1.

Notes:

a) The values indicated are averages for the cable types and the range of sections in table 3.

b) The factors are applicable to cables grouped in a single layer, as shown above, and do not apply to cables arranged in more of a layer. The values for such provisions may be significantly lower and must be determined by an appropriate method; table 8 can be used.

c) The values are indicated for a vertical distance between trays or beds of 300 mm. For shorter distances, the factors must be reduced.

d) The values are indicated for a horizontal distance between trays of 225 mm, these being mounted bottom to bottom. For smaller spacings, the factors must be reduced.

e) For circuits containing several cables in parallel per phase, each group of three conductors must be considered as a circuit for the application of this table.

Table 12 - Presence of harmonics

Notes:

a) In the presence of harmonics between 15 and 33%, use a multiplier factor of 0.86 for the current conduction tables for all phases and neutral.

b) In the presence of harmonics, the current in the neutral will be higher than that in the phases, therefore the neutral section will tend to be larger. To calculate, apply the factors above to the design current (remembering that the design current must contain harmonic components).

In = lb x fx

Where:

ln = neutral current

lb = design current

fh = correction factor

Using this value, check the neutral section in the current capacity tables (use circuit columns with 3 conductors).

Table 13 - Minimum sections of copper conductors depending on use

Notes:

a) In signaling and control circuits intended for electronic equipment, sections of up to 0.1 mm² are permitted;

b) In flexible multipolar cables containing seven or more veins, sections of up to 0.1mm² are permitted;

c) Current taking circuits are considered as power circuits.

Table 14 - Sections of neutral and protective conductors

• In the case of color identification for the neutral conductor, it must be light blue in the insulation of the insulated conductor or the core of the multipolar cable.

• In the same situation for the protective conductor (PE), it must be identified by a double color, green-yellow or, failing that, the color green. For the conductor with dual function of neutral and protection (PEN), it must be identified in light blue with yellow-green washers at visible or accessible points.

• In three-phase systems, the neutral section or conductor may be smaller than that of the other phase conductors, respecting the minimum values given above, provided that the following two conditions are simultaneously met:

a) when the presence of harmonics is not expected;

b) the maximum current that could flow through the neutral conductor in normal service is lower than the current carrying capacity corresponding to the reduced section of the neutral conductor

Table 15 - Rated currents of three-phase cage motors (60hz)

Observation: * For 440 V motors, multiply the currents for 220 V motors by 0.5

Voltage drop limits

a) 7% calculated from the secondary terminals of the MV/LV transformer, in the case of a transformer owned by the consumer unit(s).

b) 7% calculated from the secondary terminals of the MV/LV transformer of the electricity distribution company, when the delivery point is located there.

c) 5% calculated from the delivery point, in other cases of delivery point with secondary distribution voltage supply.

d) 7% calculated from the generator output terminals, in the case of an own generator set.

Observations:

1 – These voltage drop limits are valid when the nominal voltage of the equipment intended for use coincides with the nominal voltage of the installation.

2 – Delivery point: Connection point of the electricity distribution company's electrical system with the electrical installation of the consumer unit(s) and which delimits the distributor's responsibilities, defined by the regulatory authority.

3 – In the cases of paragraphs a), b) and d), when the main lines of the installation are longer than 100 m, the voltage drops can be increased by 0.005% for half a meter of line longer than 100 m, without However, this supplementation is greater than 5%.

4 – For motor circuits, at start-up, the drop must not exceed 10%.

5 – in no case can the voltage drop in the circuits exceed 4%.

6 – Voltage drops greater than those indicated in 6.2.7.1 are permitted for equipment with high starting current, during the starting period, as long as they are within the limits allowed in their respective standards.

Table 16 - Voltage drop in V/A.km

Notes:

a) The dimensions of the conduit and cable tray adopted are such that the area of the cables does not exceed 40% of their internal area;

b) Conductor temperature: 70 ºC.

Table 17 - Voltage drop in V/A.km

Notes:

a) Conductor temperature: 70 ºC;

b) Valid for installation in non-magnetic conduit and directly buried;

c) Applicable to direct fixing, to wall or ceiling, pit, building space, tray, shelf, supports on insulators and overhead lines;

d) Also applicable to 750V Innovcable insulated conductors, on insulators and in overhead lines.

Table 17A - Voltage drop in V/A.km

a) Temperature in the conductor: 90 ºC;

b) Valid for installation in non-magnetic conduit and directly buried;

c) Applicable to direct fixing, to wall or ceiling, or open, ventilated or closed cable tray, building space, tray, shelf, supports and on insulators

Maximum short-circuit currents INNOVCABLE Cables - BWF 0.6/1kV

Maximum conductor temperature in continuous operation: 70ºC

Maximum conductor temperature in short circuit: 160ºC